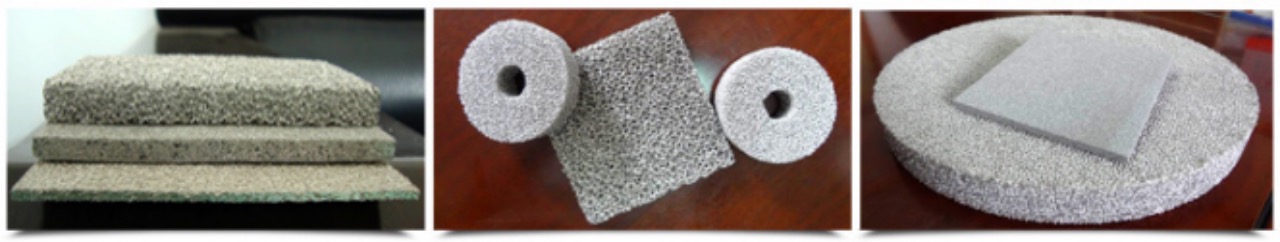

Foamed nickel is a kind of sound-absorbing material with excellent performance. It has a high sound absorption coefficient. The design of the sound-absorbing structure can improve its sound absorption performance at low frequencies. Nickel foam is also one of the better electrode materials for the manufacture of cadmium-nickel batteries and hydrogen-nickel batteries. Shielding materials, precious metal replacement and recycling, and many other fields.

The basic characteristics of fog metal:

1. High porosity: Almost fully permeable structure with a porosity of more than 98%, as a material filtration, low pressure drop and high flow rate;

2. Larger than the original: under the same through-hole ratio, it is preliminary compared with other raw materials;

3. High pore activation and fine particle activity adjustment: the porosity reaches more than 95%, it is a three-dimensional mechanically transparent structure, and has better metal strength, uniform volume, and lighter material weight. Storage battery, heat exchange.

The nickel foam industry is in a good operating and development situation. The development is gradually moving towards industrialization and large-scale development. The process of preparing foam nickel by electrodeposition technology has been successfully developed through experiments. The foam nickel is a sound-absorbing material with excellent performance. With high sound absorption coefficient, the sound absorption performance at low frequencies can be improved through the design of the sound absorption structure. Nickel foam is also one of the electrode materials with a good price comparison for the manufacture of cadmium-nickel batteries and hydrogen-nickel batteries. The process of preparing nickel foam by electrodeposition technology has been successfully developed through experiments. The matrix material used is porous open-cell foam. The conductive layer can be prepared by electroless nickel plating, vacuum nickel plating and conductive glue (sol, submicron graphite emulsion, etc.). The conductive layer can be prepared by pre-plating nickel. Thick nickel is electroplated in a general-purpose sulfate nickel plating electrolyte, and then burned, reduced, and annealed to obtain a three-dimensional reticulated nickel foam material with excellent performance.

The uses of foamed nickel are:

One is the battery electrode material foam nickel is mainly used for battery electrode materials, especially for NiMH batteries, which are widely used in laptop computers, mobile phones, electric scooters, electric bicycles, and hybrid vehicles.

The second is the fuel cell. The usual working temperature of molten carbonate fuel cell is between 550-700℃. Foamed nickel can become the electrocatalyst of molten carbonate fuel cell. Foamed nickel can be used as a modified material for the bipolar plate of a proton exchange membrane cell (PEMFC), an electrode relay feeder for a solid oxide fuel cell (SOFC), and an electrode material in electrolysis (such as in a water electrolyte environment). Increasing the surface area can also be used to generate hydrogen and syngas for fuel cells.

Nickel foam is an important part of the battery. It can be said that we people cannot do without the battery, which means that we cannot do without the nickel foam. It is used in all aspects of life.