BEIHAI Composite Foam Metal

BEIHAI Composite Materials Group is a big group which has over 2300 workers with 6 different factories. We are special for producing different building materials for over 26 years.

We are the first company in China who has set up own factory producing AFP(Aluminum Foam Panel).We have a group of technical core who have high technique and many years’ actual working experience.

BEIHAI AFP dept.is a company of specialization integrating material of foam metal and researching and developing, producing, running of related product, application engineering of the product and related technical service into one.The main product of BEIHAI AFP is Aluminum Foam Panel, and now the company owns the proprietary intellectual property rights in producing , making and application of foam aluminum.

As the Aluminum Foam products with light weight, high sound absorption, high shock absorption, high absorption of impact energy, high electromagnetic shielding performance, excellent heat insulation, high temperature, fire resistance, with unique environmental friendliness and other special properties.

It can be used in the following sites to eliminate sound and to stop noise: pipeline silencers, head mufflers, plenum chambers, purification workshops, food-producing workshops, pharmaceutical factories, manufacturing shops of precise instrument, laboratories, wards and operating rooms, canteens, boats and passenger compartments, cabins, air-conditioning and ventilation equipment.

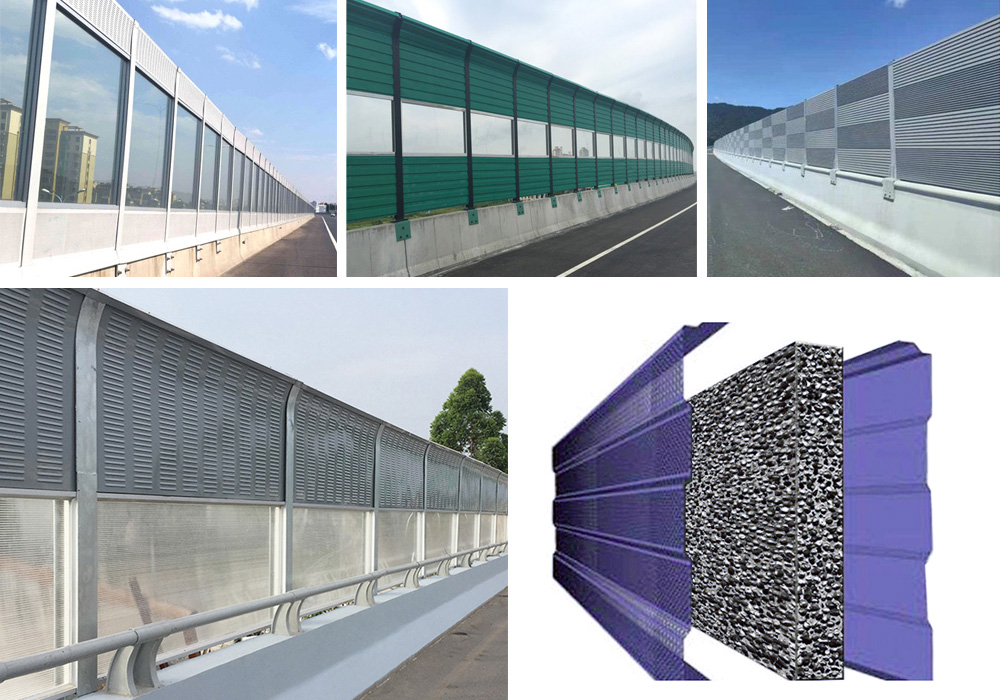

In order to reach best sound absorption effect in outdoor, highway, railway, etc., we have developed a special processed AFP . We punch holes regularly on the AFP as a proportion of 3%. This special AFP has greatly improved sound absorption capacity.

The production process of open-celled aluminum foam is to melt the aluminum, aluminum-silicon or aluminum-magnesium which is melted, and then to be molded by die-casting.Open cell AFP is sound absorbing, ventilated, fireproof, ultralight 100% eco-friendly & recyclable, etc.

Copper Foam has been widely used as the preparation of the battery negative carrier material, electrode substrate of lithium ion battery or fuel, cellcatalyst carrier and electromagnetic shielding materials. Especially copper foam is the base material used as an electrode of the battery, with some obvious advantages.

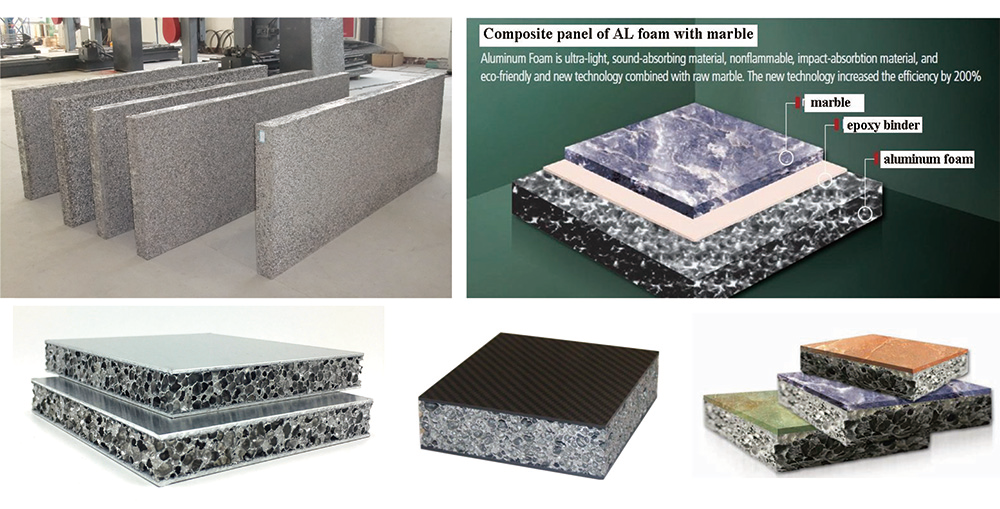

Porous metal foam is a new type of porous structure metal material with a certain number and size pore size and a certain porosity. The material has the characteristics of small bulk density, large specific surface area, good energy absorption, high specific strength and specific rigidity.

Exploring the strength and versatility of aluminum foam sandwich structures

Aluminum foam sandwich structures are a revolutionary material that is gaining traction in various industries due to its exceptional strength, lightness and versatility. But what exactly is an aluminum foam sandwich? Why has it become a popular choice for many applications? An aluminum foam sandwich is a composite material consisting [...]

Innovative Building Materials: Aluminum Foam Comes to the Fore in Interior and Exterior Wall Decorations

In recent years, a new building material for interior and exterior wall decoration called aluminum foam has come to the forefront of the market and attracted a great deal of attention. Aluminum foam has become an innovative choice for the construction industry due to its unique properties and diverse applications. [...]

Highway Sound Barrier Spot Cooling Tower Noise Reduction Noise-Absorbing Wall in Small Area

Our company has launched spot highway sound barriers, cooling tower sound insulation and noise reduction and community sound-absorbing walls, which provide innovative solutions to solve the problem of urban noise pollution.