Aluminum foam sandwich structures are a revolutionary material that is gaining traction in various industries due to its exceptional strength, lightness and versatility. But what exactly is an aluminum foam sandwich? Why has it become a popular choice for many applications?

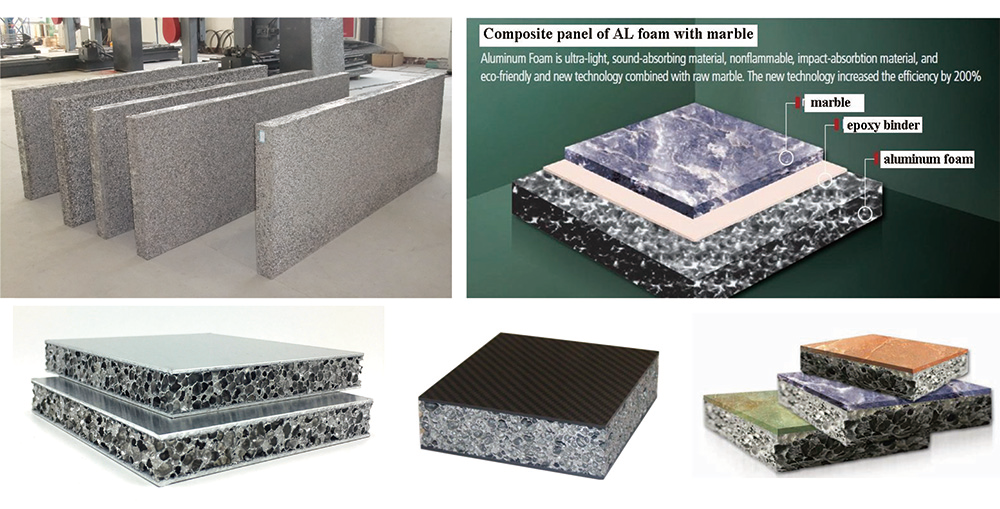

An aluminum foam sandwich is a composite material consisting of two thin aluminum sheets bonded to a lightweight aluminum foam core. This unique combination creates a material that is extremely strong and stiff, yet significantly lighter than solid aluminum or other traditional materials. Foam core provides excellent energy absorption and impact resistance, making it ideal for applications where weight reduction and structural integrity are critical.

One of the main advantages of aluminum foam sandwich structures is their high strength-to-weight ratio. This makes them an excellent choice for applications requiring weight reduction, such as the aerospace and automotive industries. The material’s lightweight nature also helps improve fuel efficiency and overall performance.

In addition to its strength and lightweight properties, aluminum foam sandwich structures offer excellent thermal and acoustic insulation properties. This makes them suitable for use in building and construction, as well as in the manufacture of transport vehicles, where noise reduction and temperature control are important factors.

In addition, foam aluminum sandwich structures are highly customizable and can be tailored to specific design requirements. They can be easily shaped, cut and shaped to fit a wide range of applications, making them a versatile choice for engineers and designers.

Overall, the unique combination of strength, lightness, and versatility makes aluminum foam sandwich structures a compelling choice for a variety of applications. As technology continues to advance, we expect to see more innovative uses for this remarkable material in the future.