Ceramic Foam Filter

Ceramic Foam Filter

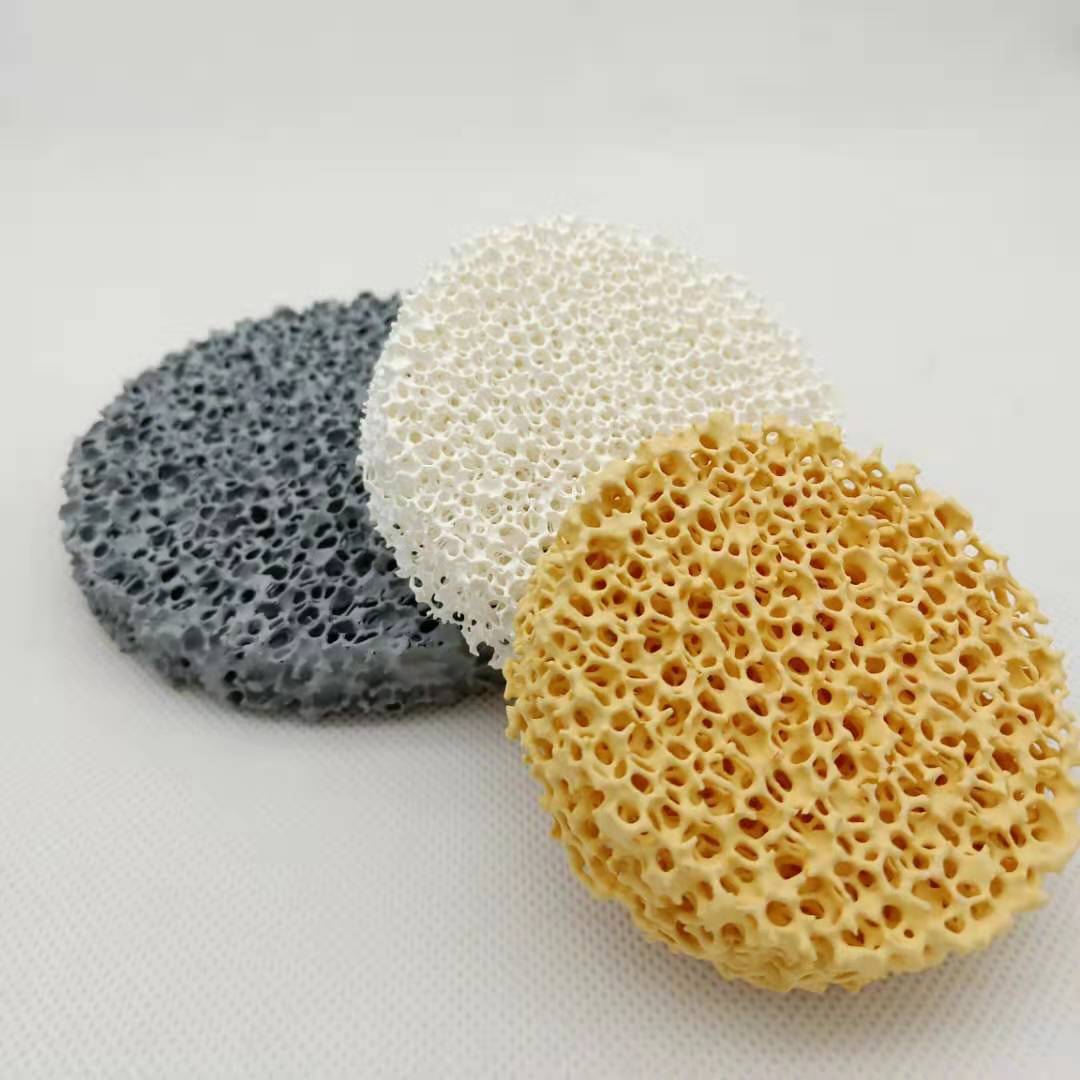

The basic materials of foam ceramic filter are silicon carbide, zirconium oxide and aluminum oxide.

Foam ceramic filters have excellent filtration effect on copper or iron water, utilizing three-dimensional structure, effectively removing oxidized inclusions and other non-metallic inclusions through blocking and capturing adsorption. Whether it is gray iron, ductile iron or axle body, cylinder body or complex large parts, precision hardware parts after filtration, product quality will get satisfactory results.

Production Description

Foam ceramic filter products, development began in the 1970s, after decades of rapid development, manufacturing products made of: silicon carbide, zirconia, alumina, graphite, etc.; applications include cast steel, cast iron, cast aluminum, cast copper filtration. Foam ceramic filter can greatly improve the surface quality and performance of castings.

Foam ceramic filter is a special ceramic product with three-dimensional three-dimensional mesh structure sintered at high temperature by using polyurethane foam as the precursor, dipping refractory slurry molding process. Classification by material: alumina, magnesium oxide, silicon carbide, zirconia, carbon composite material; by mesh density ppi classification: 10ppi, 15ppi, 20ppi, 25ppi, 30ppi, 40ppi, 50ppi, 60ppi.

Product Performance

Foam ceramic filter has a unique three-dimensional connecting curved pore mesh skeleton structure and 80%~90% open porosity. It has four filtration and purification mechanisms, i.e., sieve-cake-deep-bed filtration mechanism, floatation separation mechanism, deep filtration (physical adsorption) and rectification mechanism. It can efficiently filter out large inclusions and most of the tiny suspended inclusions as small as tens of microns in the metal liquid. Compared with refractory fiber filters and straight hole honeycomb ceramic filters, etc., it is characterized by high refractoriness, high strength, good filtration effect and high filtration efficiency.

Process Requirement

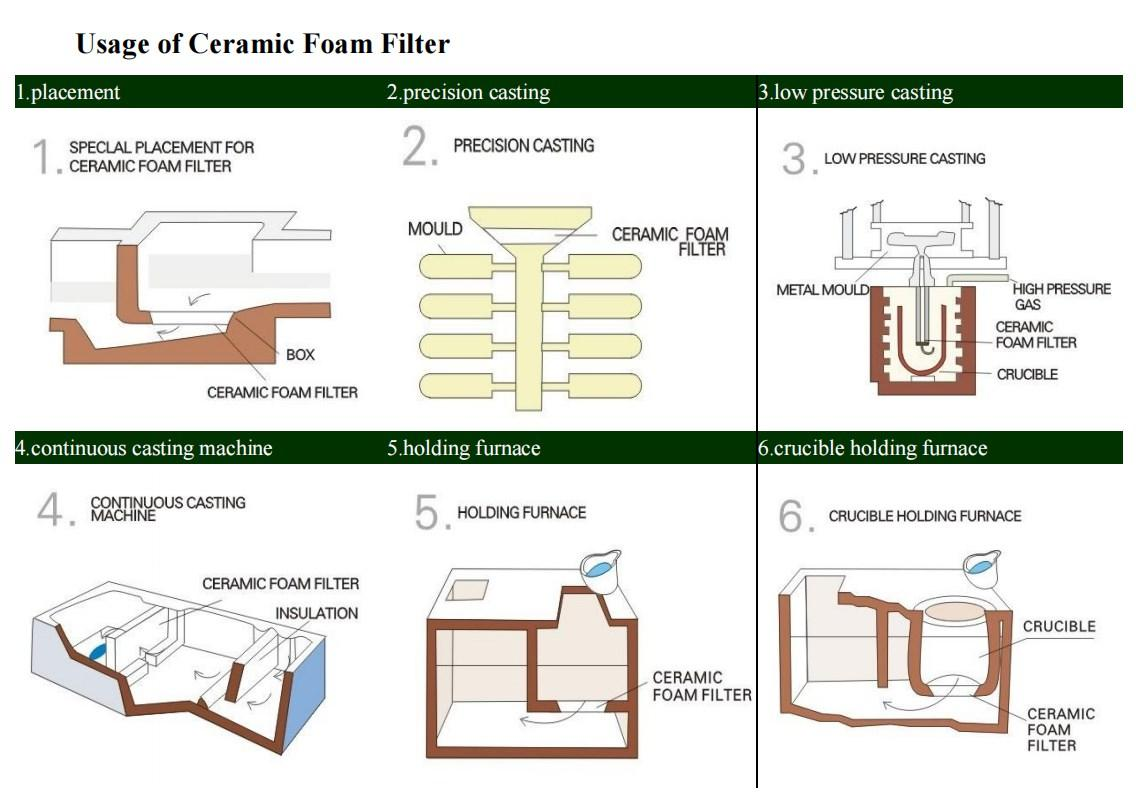

The use of filtration process is mainly based on the following considerations, on the one hand, filtration makes the flow of aluminum liquid orderly and relatively calm, while on the other hand, the solid slag in the metal liquid is effectively removed, and the quality of castings is rapidly improved.

Alumina foam ceramic filtration products effectively remove solid inclusions in the molten metal, so that aluminum alloys can be smoothly processed in forging, aluminum foil manufacturing, extrusion, and other processes to obtain perfect aluminum products. The products are available in a selection range from 10ppi coarse porosity to 70ppi very fine porosity, so there will always be a product standard that suits your requirements. Normal sizes and special sizes requested by customers can be met.

Product Application

Foam ceramic filter is also adapted to copper, bronze, brass and other copper alloys to reduce copper liquid turbulence and rectify and purify molten copper liquid. It is especially valuable that the copper castings purified by filtration in the marine ship turbine, chemical parts and other high-demand or severe environment life significantly longer, and for the surface polishing requirements of the cast copper parts also have good results. In the traditional copper industry and electrical and electronic copper industry and continuous casting and rolling process foam ceramic filter also plays an important role. Because copper and alloys, including zinc alloy has a greater specific gravity, in the casting of a greater thermal shock, so in the cast copper process, the use of silicon carbide foam ceramic filters are generally on the size of strict regulations.

Instructions for use

Workshop

Packing Details

FAQ

1.MOQ: 100m²

2.Delivery time: around 20days after confirm order.

3.For LCL goods, the payment terms is 100% T/T payment in advance.

4.For full container, the payment terms is 50% deposit in advance, 50% balance before the shipment date.