The performance characteristics and applications of porous metal foam

Since the advent of porous metal foam material, as a structural material, it has the characteristics of light weight and high specific strength. As a functional material, it has porous, vibration reduction, damping, sound absorption, sound insulation, heat dissipation, impact energy absorption, electromagnetic shielding, etc. Such physical properties, so it has been more and more widely used in general industrial fields and high-tech fields at home and abroad. Specific applications are as follows: Use its vibration damping and damping properties to make buffers and shock absorbers, such as spacecraft landing gear, elevator transmission safety mats, various packaging boxes, especially air transport packaging boxes, machine bed, base, reduction Gear vibration and noise damping ring, high-speed grinder energy-absorbing lining, this application can also be regarded as the application of sound absorption and sound insulation performance of porous metal foam; using its electromagnetic shielding, light weight and excellent sound absorption and sound insulation performance, it has It is used in the production of sound insulation panels, electronic instrument housings and electrical shielding rooms in the construction industry; its porosity has been used in chemical filters, gasification processors for water purification, oil-containing bearings for automatic refueling, Scented decorations, etc., take advantage of their light weight and high specific strength to make water floats, sports equipment (such as sledges, etc.), and corresponding parts of aerospace vehicles.

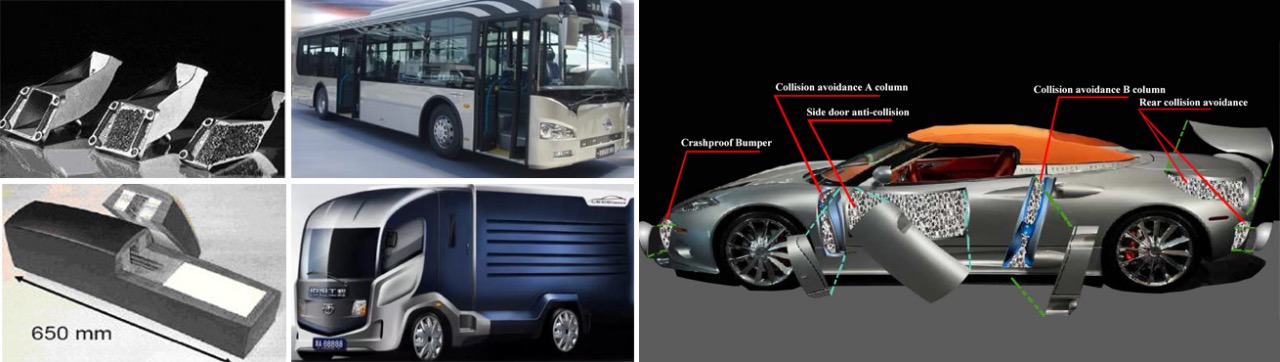

According to relevant reports, the use of porous foamed metal materials to make the aircraft not only has the advantages of reducing weight and saving energy, but also has the advantage of allowing it to return to the atmosphere when the space station ends its mission and burn quickly and completely in the atmosphere. , Into gas, reduce space waste; use of its heat dissipation performance, has been used to make radiators; use of its shock absorption, vibration reduction, damping performance, has been used to make anti-shock components on the side and front of cars, trains, and military armored vehicles Impact protection materials, etc. The application progress of foamed metal filters and separators, porous electrode materials, heat exchangers, catalytic matrix materials, vibration damping materials, electromagnetic shielding materials, biomedical porous materials, etc.

Application of aluminum foam

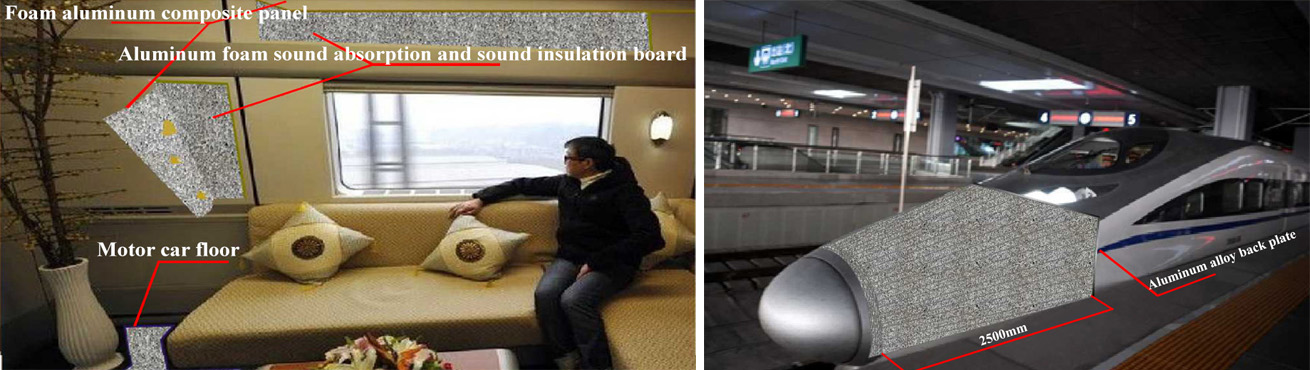

As ships have increasingly higher requirements for quietness and lightness, the requirements for materials continue to increase, especially for ultra-light structures and multi-functional materials. As a new type of multifunctional material, foamed aluminum has the characteristics of light weight, high specific rigidity, sound absorption and sound insulation, heat insulation, shock resistance, impact resistance, excellent electrical performance and recyclability, etc. It is used in the fields of sea, land, and air weapons, equipment, and civilian use. It has huge application prospects. The application of foamed aluminum as a structural material and the application of foamed aluminum as a functional material: energy absorbing materials and shock absorption materials, sound absorbing materials, electromagnetic shielding materials, heat exchange materials, heat insulation materials, and filter materials. Using foam aluminum’s low density, high rigidity, sound insulation, heat insulation, fire resistance, energy absorption and no toxic gas when heated, it is widely used in the rail transit industry, such as heat insulation, sound insulation, and energy absorption in carriages and containers And fire-proof and anti-virus parts.

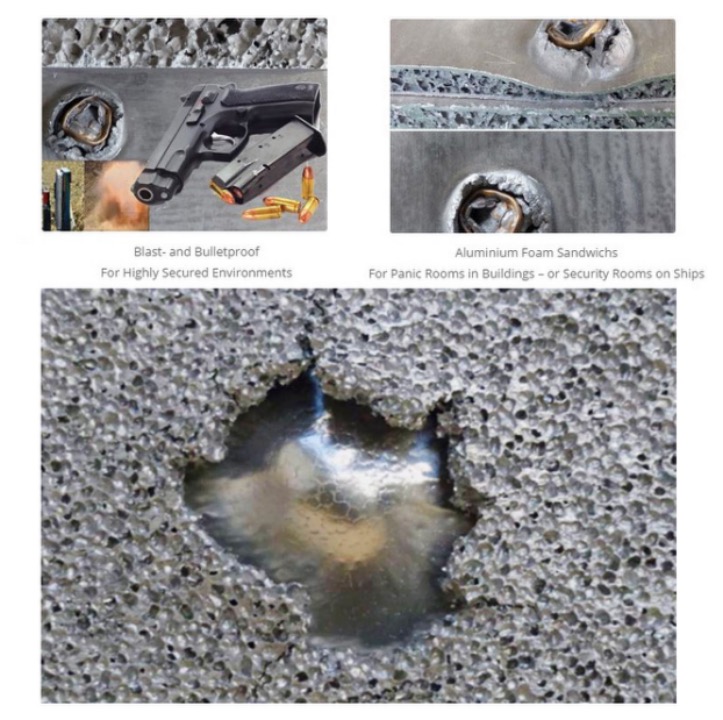

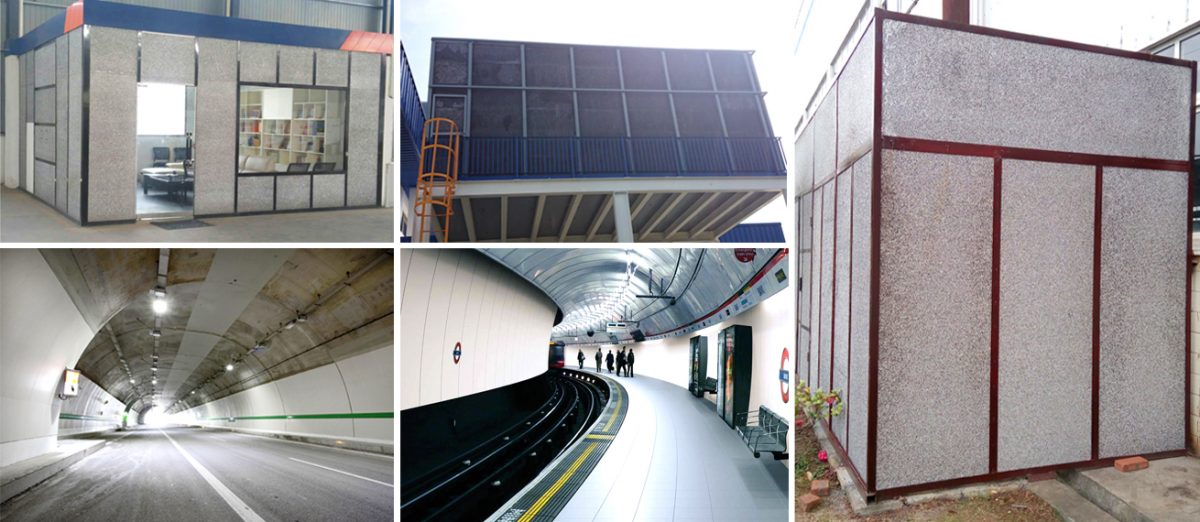

Utilizing the sound insulation, sound absorption and energy absorption properties of foamed aluminum, it is used in environmental protection fields in urban construction, such as: sound insulation screen; automobile manufacturing is used in energy absorption and sound absorption components, such as: bumpers and silencers. Utilizing the low density, high rigidity, and low thermal conductivity of foamed aluminum, it is widely used in energy-saving buildings, such as: heat-insulating walls, fire-resistant and heat-insulating doors, and energy-saving mobile homes. The sound absorption and antimagnetic properties of foamed aluminum can also be used in the military industry, such as armored vehicles and submarine shell sandwich panels. In the fields of machinery manufacturing, aviation industry, etc., foamed aluminum can be used as heat-insulating, sound-proof, shock-proof, and energy-absorbing components. The functional material of foamed aluminum has been industrialized in developed countries, such as the United States, Japan, Canada, Germany, and South Korea. Dozens of units in my country are already studying the industrialized production of foamed aluminum, and some of them have been put into large-scale production, which can produce valuable products.

To sum up, the application of foam metal is quite extensive. It can be used in many fields such as construction, aviation, computer, transportation and packaging industry, and with the continuous improvement of foam metal production technology and the continuous deepening of its research and development, The application field of foam metal is still expanding. Therefore, the research and development of foam metal has great practical application value.