Foamed nickel is a sound-absorbing material with excellent performance, which has a high sound absorption coefficient at high frequencies; the design of the sound-absorbing structure can improve its sound absorption performance at low frequencies. Nickel foam is also one of the best electrode materials for cadmium-nickel batteries and hydrogen-nickel batteries.

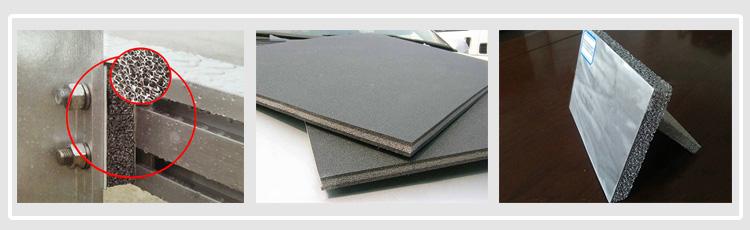

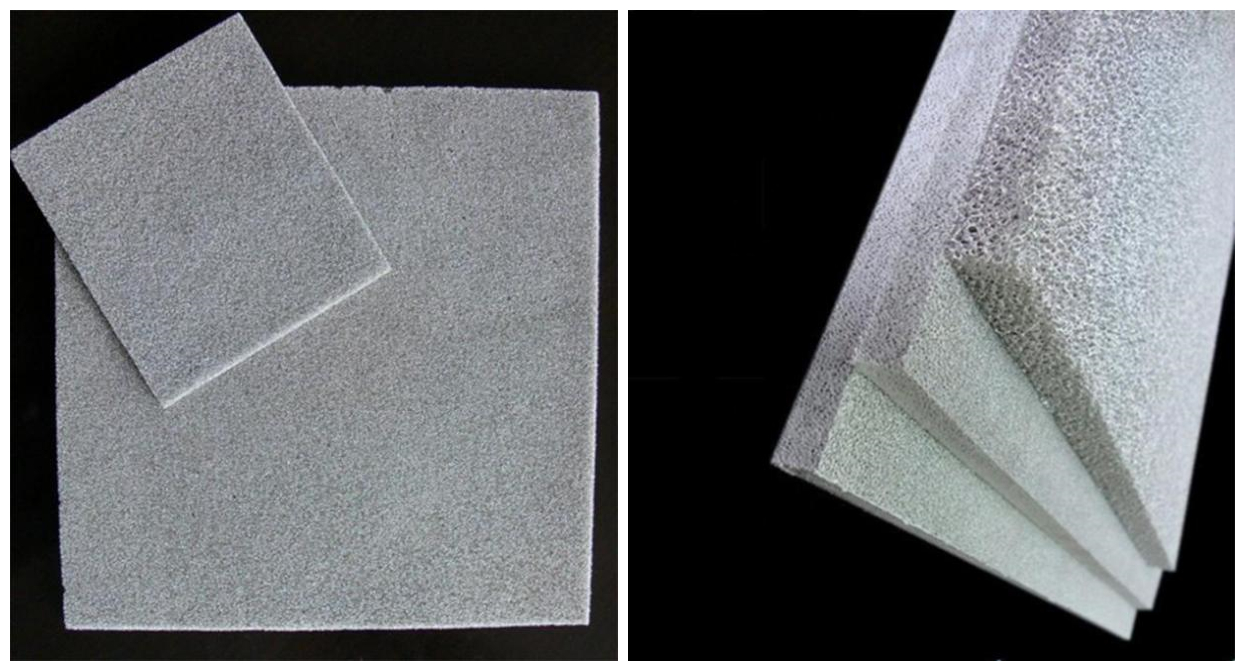

The process of preparing nickel foam by electrodeposition technology has been successfully developed through experiments. The matrix material used is porous open-cell foam. The conductive layer can be prepared by three methods: electroless nickel plating, vacuum nickel plating and conductive glue (palladium sol, submicron graphite emulsion, etc.). Thick nickel is electroplated in the general-purpose sulfate nickel plating electrolyte, and then the three-dimensional reticulated nickel foam material with excellent performance can be obtained by burning, reducing, and annealing.

Sponge-like porous metal nickel, iron, copper and their composite layer porous bodies can be used as filter carriers, chemical catalyst carriers, electromagnetic shielding materials, precious metal replacement and recovery, and many other fields.

Battery electrode material

Nickel foam is mainly used for battery electrode materials, especially for NiMH batteries. This rechargeable battery is widely used in laptop computers, mobile phones, electric scooters, electric bicycles, and hybrid vehicles.

The fuel cell

The usual operating temperature of molten carbonate fuel cells is between 550-700°C, and foamed nickel can be used as an electrocatalyst for molten carbonate fuel cells. Foamed nickel can be used as a modified material for the bipolar plate of a proton exchange membrane cell (PEMFC), an electrode relay feeder for a solid oxide fuel cell (SOFC), and an electrode material in electrolysis (such as in a water electrolyte environment). Increasing the surface area can also be used to generate hydrogen and syngas for fuel cells.

Catalyst material

The unique open-cell structure, low-pressure input hole, inherent tensile strength and thermal shock resistance make foamed nickel possible to become a catalyst carrier for automotive catalyst converters, catalytic combustion, and diesel black smoke purifiers. When the engine is cold-started, carbon monoxide and hydrocarbons are converted. Due to the thermal conductivity, the foamed nickel catalyst carrier may be superior to the ceramic catalyst carrier. In this sense, the foamed nickel can be compared with or more resistant to high temperature steel catalyst carrier. The steel catalyst carrier is more superior. Other applications of foamed nickel catalysts may include Fischer-Topsch reaction, gas modification, and hydrogenation reaction foam catalyst carrier for fine chemicals.

Other applications

Foamed nickel can be used as a filter material, a magnetic current conductor for treating magnetic particles in fluids. Other applications include hydrogen storage media and heat exchange media. The development situation of China’s foam nickel industry is good, and enterprises in this industry are gradually developing towards industrialization and large-scale development. Foamed nickel is a sound-absorbing material with excellent performance, which has a high sound absorption coefficient at high frequencies; the design of the sound-absorbing structure can improve its sound absorption performance at low frequencies. Nickel foam is also one of the best electrode materials for cadmium-nickel batteries and hydrogen-nickel batteries. The process of preparing nickel foam by electrodeposition technology has been successfully developed through experiments. The matrix material used is porous open-cell foam plastic. The conductive layer can be prepared by three methods: electroless nickel plating, vacuum nickel plating and conductive glue immersion. After pre-plating nickel, it can be electroplated thickly in general sulfate nickel plating electrolyte. Nickel, after sintering, reduction, and annealing process, a foamed nickel material with excellent performance can be obtained.