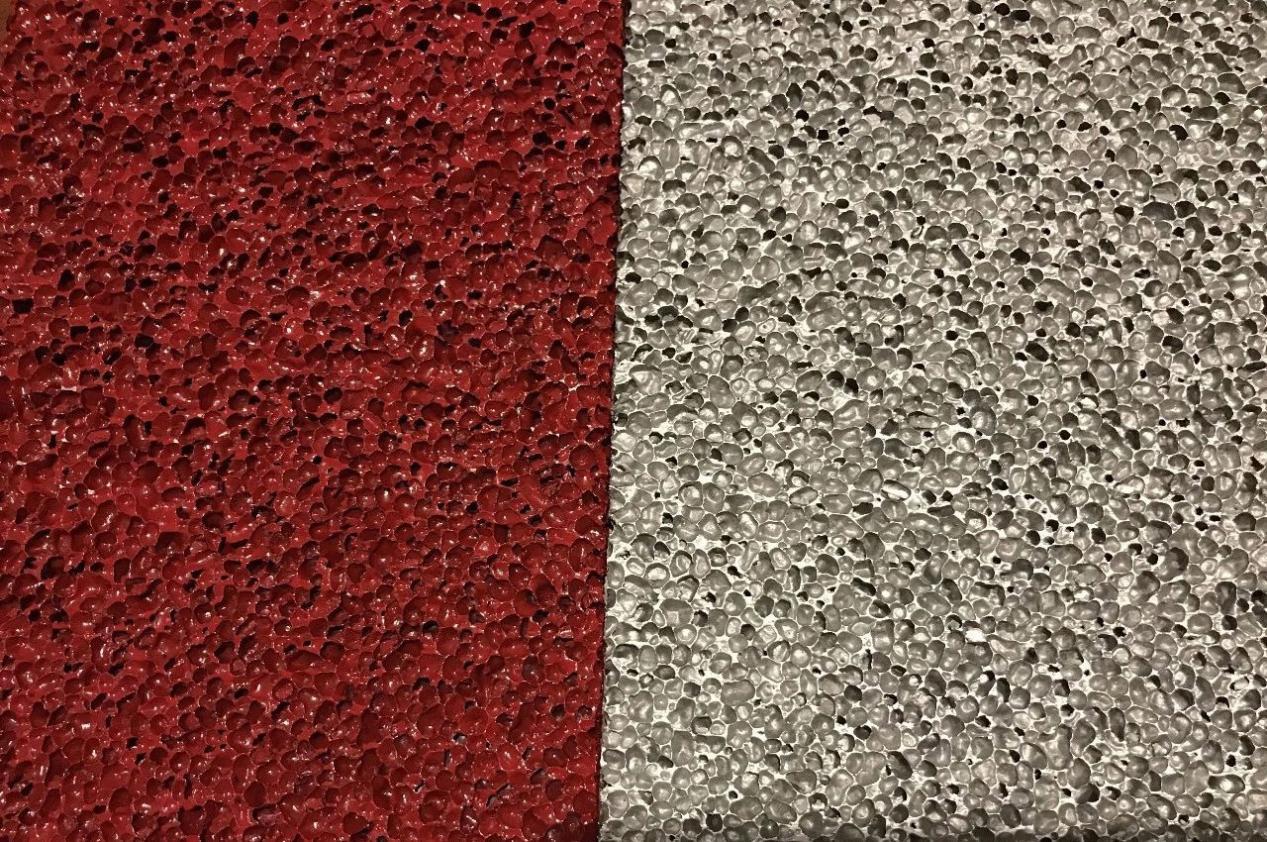

Yes, you read that right, metal aluminum can blow bubbles. This is the new member of our aluminum alloy product family-aluminum foam.

Lightweight, floatable, sound-absorbing and heat-insulating.

Fireproof and easy to process, high magnetic shielding strength.

Foamed aluminum has many advantages that other metals can’t match, such as high strength, light weight, impact energy absorption, anti-vibration, anti-noise, non-toxic and 100% recyclable advantages.

1. Lightweight

The density meter is about 1/10 of pure aluminum, 1/20 of iron, and 1/4 of wood and plastic.

2. Sound absorption

When the sound enters the foam, diffuse reflection occurs and interferes with each other, so that the sound energy is converted into heat energy and the noise is weakened.

Compared with other sound-absorbing materials, the low-frequency absorption performance is excellent, plus a certain size cavity, the sound absorption effect is better, and it can be used in a wider frequency range.

For example: before the indoor sound absorption treatment, the wall is made of very hard cement. After the room is pasted with 10mm thick foam aluminum panels for sound absorption and noise reduction treatment, the sound absorption can reduce the noise by 20-30dB.

3. Sound insulation

It can be compounded with other sound insulation materials. Due to the sound absorption of foamed aluminum, the sound insulation effect can be further improved.

4. Fire prevention

It has good fire resistance. The melting point of aluminum is 660℃, and the foamed aluminum does not start to soften until it reaches 800℃ (because it cannot bear its own weight), but it has not melted yet.

In the absence of external force, it will not deform even if exposed to a high temperature of 780℃, and will withstand higher temperatures than ordinary sound-absorbing materials.

In addition, foamed aluminum is a non-combustible material and will not generate harmful gases like plastics and other materials.

5. Electromagnetic shielding

It has excellent electromagnetic shielding performance and also has sound absorption characteristics.

It is most suitable for making ceilings and walls of electrical equipment rooms as electromagnetic shielding materials.

6. Good energy absorption and buffering

When the pressure reaches the yield point, the bubble diaphragm is deformed, continuously deforming layer by layer, the bubble is destroyed, and a great compression deformation is generated, thereby absorbing the impact energy and showing a good cushioning effect.

7. Easy to process

It is easy to perform mechanical processing, such as cutting, drilling, bending and embossing.

The aluminum foam board can be cut into different specifications and sizes with a saw, which can be easily drilled and riveted, can also be bent and embossed, and can be bonded to each other with adhesive.

8. Convenient construction

Light weight, can be installed manually, especially suitable for ceilings, walls, roofs and other high places.

Because of the convenience of processing, bonding and riveting can be carried out, and it is very easy to connect with other structures. Therefore, it is convenient for on-site construction and installation combination.

9. Good surface decoration effect

Using a special process, the outer surface can be painted with paint.

Coating hardly damages its sound-absorbing effect.

10. can be used as a sandwich

Bonding aluminum, copper, titanium and other thin plates on both sides to form a sandwich plate, which can be made into a lightweight and high-strength plate, and can be used as a structural material with excellent performance.