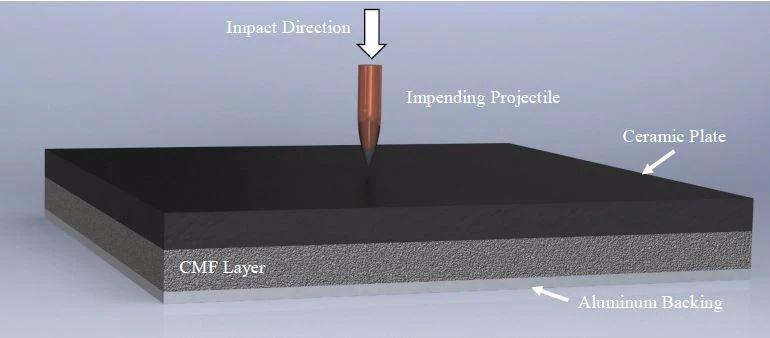

The low-density steel composite metal foam core material, together with the ceramic face plate and aluminum back plate, form a lightweight hard armor system.

Light hard armor system structure drawing

High-strength, high-hardness, and low-density high-performance armor systems are vital to military vehicles and ships. They can provide greater mobility and better respond to various ballistic weapons and explosion threats, and significantly improve survivability. The researchers used powder metallurgy to prepare a composite metal foam core composed of stainless steel hollow spheres with a diameter of 2mm and a thickness of 100μm and a 316L stainless steel matrix, and used high-strength aviation-grade epoxy resin and ceramic panels and 7075-T6 aluminum backplanes Bonded to obtain a hard armor system. The 12.7mm spherical projectile and armor-piercing projectile were tested at a speed of 500m/s ~ 885m/s, and it was found that the anti-elasticity performance of the armor system is equivalent to that of traditional steel armor, but the weight is less than half. The composite metal foam core material It can absorb 72% ~ 75% of the kinetic energy of spherical projectiles and 68% ~ 78% of the kinetic energy of armor-piercing projectiles. In addition, the research team also showed that the composite metal foam can effectively shield X-rays, gamma rays and neutron radiation, and its high temperature resistance is twice that of stainless steel substrates.

The composite metal foam will promote the development of next-generation lightweight and high-performance armor systems, and has significant application potential in space exploration and transportation of nuclear waste, explosives and hazardous materials.