Metal foams are main used in petrochemical industry, aerospace and environmental protection to manufacture purification, filtration, catalytic supports, electrodes and other devices.

Because of its strength, ductility and additivity, metal foams can be used as lightweight structural materials. This material has long been used as a core material for aircraft clamps. In the aerospace and missile industries, metallic foam is used as a lightweight, heat transfer support structure. Because it can be welded, glued or electroplated to the structure, it can be made into a sandwich bearing member. For example, the support body for the metal shell of the wing, the support body for the high temperature collapse of the anti-shell of the missile nose cone (because of its good thermal conductivity) and the landing gear of the spacecraft, etc.

In construction, metal foam is needed to make light, hard, fire-resistant elements, railings, or support for these things.

The high frequency and high speed acceleration and deceleration of modern elevator especially need the lightweight structure of foam metal which has both energy absorption and bearing characteristics to reduce energy consumption.

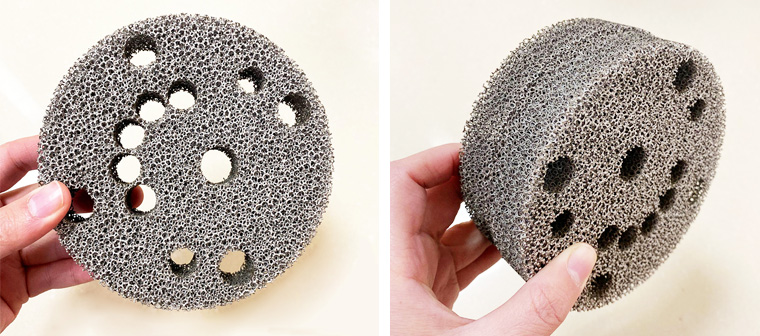

Cylindrical shells are found in a wide range of engineering structures, such as aircraft fuselages and oil platforms far from shore. Thin-walled cylindrical shells are prone to damage under loading, but if the shell is supported by continuous foam coils, the structure will have greater strength than an unreinforced central shell of the same diameter and size.

Metal foams can also be used as reinforcement materials for many organic, inorganic and metallic materials. For example, nickel foam is filled with molten aluminum and solidified into nickel foam reinforced aluminum alloy (NFRA) materials.

Metal foams are well suited for use as lightweight roll for a variety of bearing panels, shells and tube bodies, making a variety of laminated composites. A typical example of the use of porous materials for structural components is the manufacture of sandwich panels.

The sandwich panels used on modern aircraft use either glass or carbon-fiber composite skin. This skin layer is separated by metallic aluminum or paper/resin honeycomb material, and may also be separated by rigid polymer foam body to provide the sandwich panel with great specific bending stiffness and specific bending strength. The same technology has been extended to other applications where weight is a key indicator: spaceships, sleds, racing boats and movable structures.

Buffer protection is also one of the main uses of metal foam, which must have the ability to absorb energy and control the maximum force acting on the object to be protected under the limit of causing damage. Porous metal foams are well suited for this type of application.