1. Speaker features:

Sound absorption performance: The closed-cell foam aluminum plate can be perforated to make a sound absorption board with high sound absorption rate. When the opening rate is 1%~3%, the sound absorption rate is the highest. The sound absorption rate measured by the standing wave method is in the range of 1000Hz to 2000Hz, and the sound absorption rate reaches 40% to 80%.

Sound insulation effect of foam aluminum: sound insulation board made of foam aluminum sandwich panel, 20mm thick, sound insulation: 20 ~ 40dB.

2. Weather resistance:

Corrosion resistance: exposed to the marine atmosphere for one year, no obvious abnormality; under accelerated corrosion conditions, the water spray salt spray test has no abnormality for 2 years; it shows that the corrosion resistance of foamed aluminum is very good.

No moisture absorption: The moisture absorption rate of foamed aluminum is 0.0%. There is no moisture absorption, and there is no degradation of acoustic performance due to humidity.

Heat-resistant/non-combustible properties: Foamed aluminum softens at a high temperature of 600°C, and is a non-combustible material.

Insulation performance: The thermal conductivity of foamed aluminum is 0.25~0.62W/m.K, which is equivalent to that of marble, and has good insulation performance.

Thermal stability: The linear expansion coefficient of foamed aluminum is 1.934*10 ℃, which is equivalent to concrete, and it is not easy to be deformed by heat.

3. Mechanical properties:

Mechanical properties: compressive strength: 3 to 17 MPa; flexural strength: 3 to 15 MPa; tensile strength: 2 to 7 MPa;

Cushioning performance: The energy absorption can reach 8J/cm3~30J/cm3, and the foamed aluminum can absorb energy through deformation, which is an excellent impact energy absorption material.

4. Machining performance:

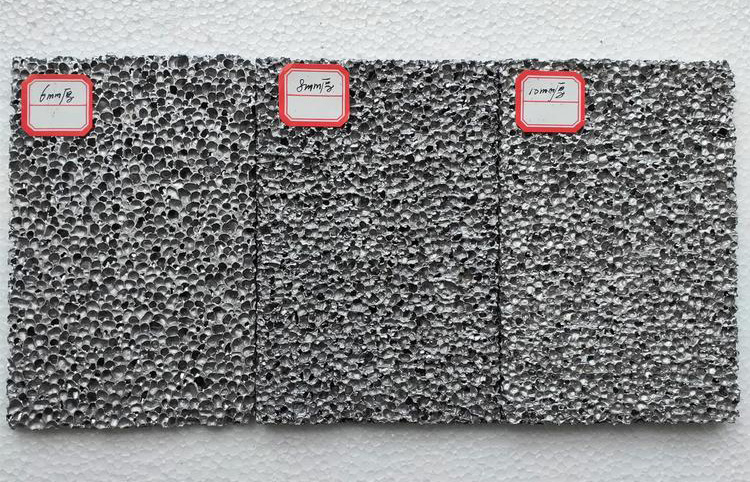

Aluminum foam is widely used in various fields. It is a porous, light and silver-white metal material with excellent characteristics of easy processing. It can be sawed, cut, planed, milled, etc., and can be easily processed into plates and strips. Bars and various special-shaped parts.

5. Green environmental protection:

Non-toxic: Aluminum foam is a composite material composed of metal and pores, which is non-toxic and will not escape toxic gases at high temperatures.

Recyclable: The main chemical components of aluminum foam are aluminum alloys and their oxides, which can be 100% recycled without causing any pollution to the environment.

Electromagnetic shielding: Electromagnetic shielding (below 200MHz) shielding electromagnetic shielding 90dB, with excellent electromagnetic shielding performance.

6. Product application fields

Due to its special properties, aluminum foam products can be widely used in aerospace, aviation, high-speed trains, urban rail trains, shipbuilding, high-speed rail, construction, tunnels and sound barriers along the way. shock, high absorption of impact energy, high electromagnetic shielding performance, excellent heat insulation, high temperature resistance, fire resistance and non-combustibility. It has unique environmental friendliness.

Damping performance: Tested by Institute of Solid State Physics, Chinese Academy of Sciences, the internal friction factor Q-1 of foam aluminum reaches 6×10-3.