In our daily life, I believe everyone is very familiar with aluminum alloy! So do you know what kind of material foam aluminum is? In fact, aluminum foam is a kind of foamed metal. This new type of material itself has a very large porosity; in addition, it also has high strength, high stiffness, high temperature resistance, high shock absorption and damping.

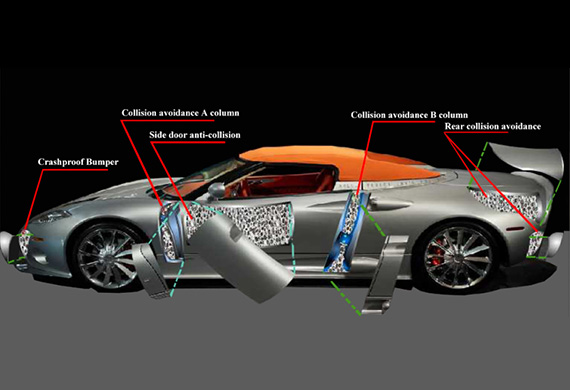

Metal foam has a series of excellent properties: high porosity, large specific surface area, high specific strength, high specific stiffness, energy absorption, good damping and shock absorption performance, corrosion resistance, high temperature resistance, electromagnetic shielding, non-toxic, easy processing, and Carry out painting surface treatment, etc. Due to its excellent physical and mechanical properties, metal foam can be used as structural materials as well as functional materials. Under normal circumstances, it has the dual functions of function and structure, and is a multifunctional engineering material with excellent performance and integration of function and structure. In recent years, aluminum foam has officially entered the application in the automotive field. Cars made of metal foam materials not only have lighter weight and reduce fuel consumption; but also because of its damping and high shock absorbability, it greatly improves the car’s anti-collision ability; It has also reached the goal of anti-collision and bulletproof.

The biggest difference between foam metal and traditional materials is that it has a kaleidoscopic micro-structure. Under the premise of maintaining high porosity, the pore size can be gradually reduced from millimeters to micrometers or even nanometers. Therefore, porous metals have good design-ability, and their micro-structures can be designed for innovative configuration optimization and multifunctional collaborative design before preparation according to the needs of different applications.

Lightweight, low energy consumption, safety and comfort are the development directions of automobiles. Improving the structure of automobiles is a way to reduce the weight of automobiles and improve fuel efficiency, but it is difficult to further reduce the space of the cab. Using a small engine or reducing other structures will bring about problems such as engine heat dissipation and collision safety caused by shortening the body. The requirement to reduce automobile noise has led to the demand for new sound-absorbing materials. Therefore, the use of lightweight and multifunctional materials to manufacture automobile parts provides a feasible solution to such problems. In the automotive industry, where material prices and quality requirements are very demanding, the use of aluminum foam parts can achieve the purpose of reducing the quality of cars, reducing unit fuel consumption, suppressing vibration, reducing environmental burdens, and increasing car safety and comfort. The applications of foamed aluminum in the automotive industry mainly include lightweight structures, energy absorbing structures and damping heat transfer structures, etc.