What is the difference between the two metal foams, copper foam and nickel foam?

1. Characteristics and advantages of copper foam

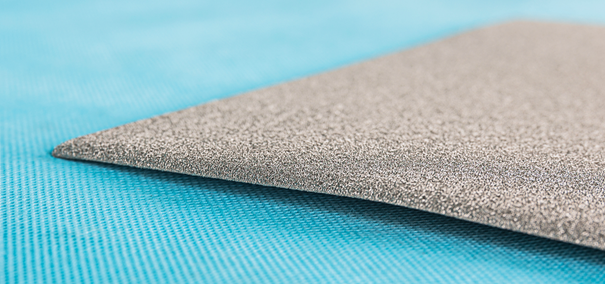

First of all, let’s take a look at the production process and characteristics of foamed copper; in the structure of foamed copper, copper is mainly used as the substrate, and a large number of holes are evenly distributed in the copper substrate during the production process. Compared with nickel foam, copper foam is lower in production cost; at the same time, copper foam also has better electrical conductivity and ductility.

2. Application field of copper foam

Copper foam itself has very good electrical conductivity because copper is used as the substrate; therefore, copper foam can be used as a substrate material for battery electrodes. Compared with foamed copper, nickel foam has more advantages in sound absorption. The copper foam has very good ductility and processing performance, and can also conduct heat and conduct electricity; and the inside of the foam copper is a three-dimensional three-dimensional porous structure, which has both electromagnetic shielding, noise reduction and shock absorption, and is very alkali-resistant and corrosion-resistant. Therefore, in the heat dissipation and heat exchange devices of CPU, graphics card, and electronic devices, copper foam is used a lot; in addition, because copper foam has very good conductivity, it is often used as electrode material for lithium electronics or fuel cells; It can be used as electromagnetic shielding materials, building materials, sound-absorbing materials, etc., and has a very wide range of applications and fields.

3. Application fields of nickel foam

Nickel foam is often used as a sound-absorbing material and is used in the creation of partition materials. Nickel foam itself also has many advantages, not only has a unique open-cell structure, but also has very good tensile, heat and impact resistance, so it is also widely used as a catalyst for organic chemical reactions and so on. At present, compared with the high temperature resistant steel catalyst and the ceramic chemical agent carrier, the foamed nickel catalyst has better performance in a sense; it is also widely used in the Fischer-Topsch reaction, gas Hydrogenation reaction foam catalyst carrier for modified, boutique chemicals.