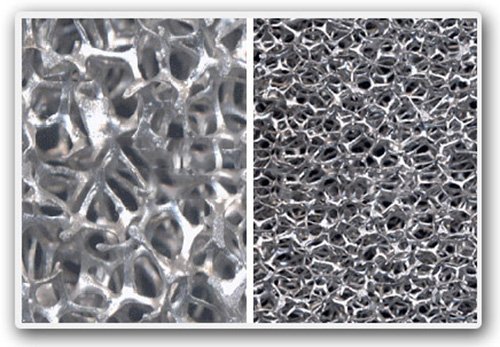

Metal foam materials have various porosity (70%-98%), pore size (100u-1000u) and filtration precision

The voids of the foamed metal filter element material are different from those of the sintered metal filter element. The through-holes present a uniform three-dimensional structure, with a maximum porosity of 98% and a through-hole rate of 99%, which is almost a full through-hole structure.

Nickel materials and their alloys have good resistance to high temperature and rapid cooling and rapid heating. It is suitable for use in the temperature range of -200-800 ℃, and has good corrosion resistance. It is suitable for a variety of corrosive media such as acids and alkalis.

Compared with traditional powder sintered filter element and wire mesh sintered filter element, the use of foam metal material to make filter element material has the following obvious advantages

1. High porosity, small flow resistance, and greatly improved flow through;

2. The opening rate is high, it is not easy to be blocked, and the replacement and cleaning cycle is prolonged;

3. Unique three-dimensional cell body through-hole structure, large dirt holding capacity, and good lateral penetration effect in the material;

4. Good strength, can be regenerated by various methods;

5. Excellent machining performance, suitable for shearing, welding, drilling, bending, riveting, thinning, etc.;

6. The filtration precision of the product can be customized according to customer requirements

The material currently has a wide range of application prospects in industrial waste gas filtration, especially in environmental protection industry, petroleum and petrochemical industry filtration