Compared with the sintered heat pipe and grooved heat pipe of the same size, the sintered heat pipe contains a large amount of copper powder filling, which reduces the capillary radius of the heat pipe and reduces the permeability. However, due to the small amount of filler in the grooved heat pipe, the large inner diameter of the capillary and the high permeability, the heat conduction efficiency of the grooved heat pipe is higher than that of the sintered heat pipe in the straight-through state.

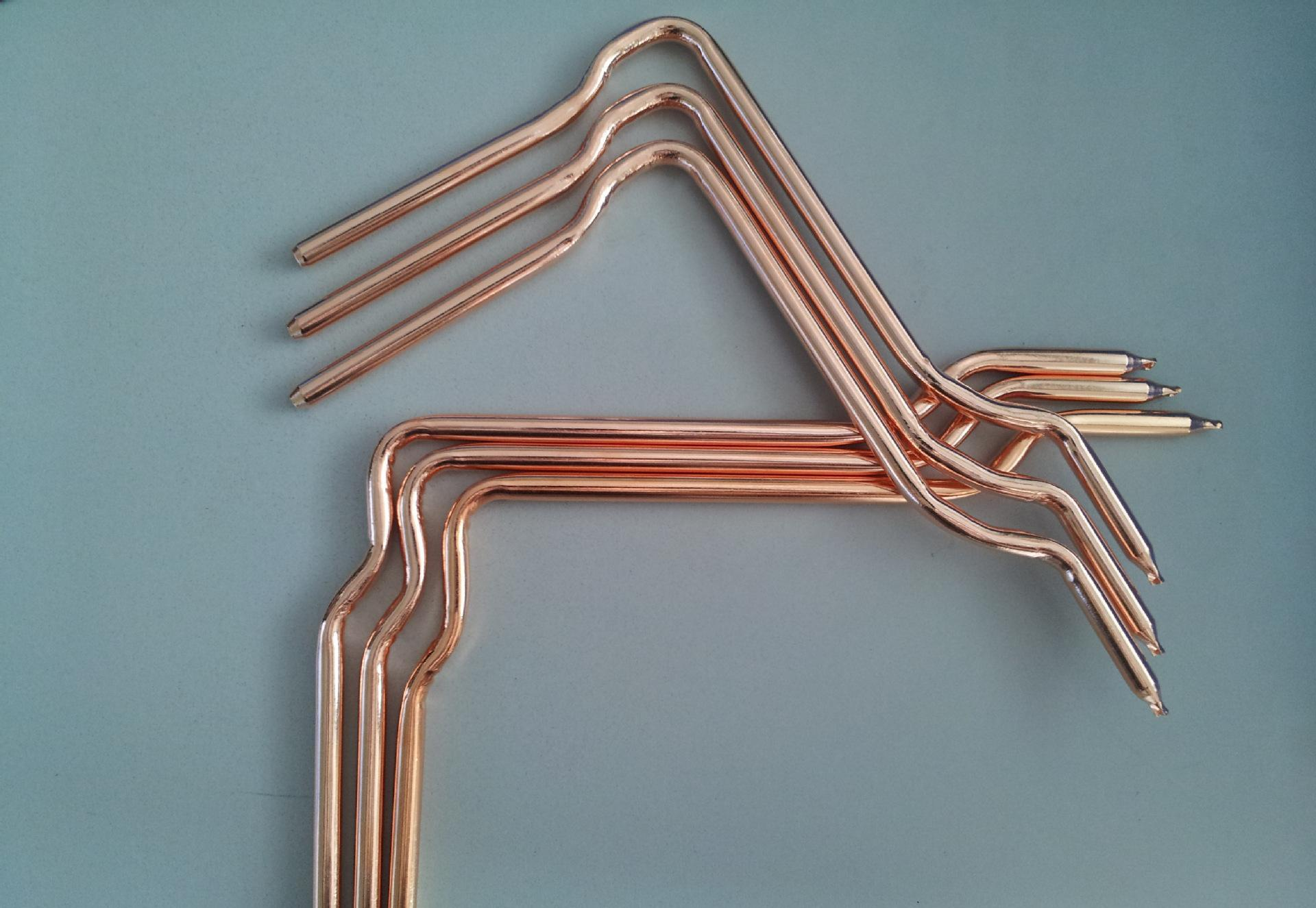

However, 90% of the water heaters on the market now use “sintered heat pipes”, why? Since the radiator heat pipes we use are all bending types, this is the fatal injury of grooved heat pipes. For grooved heat pipes, due to the limitation of the internal structure, it is very sensitive to this problem. When bent at 90 degrees, the thermal conductivity of the grooved tube is greatly reduced, and even only reaches 1/2 of the original performance. Some radiators with grooved tubes are even bent 180 degrees, and the effect can be imagined.

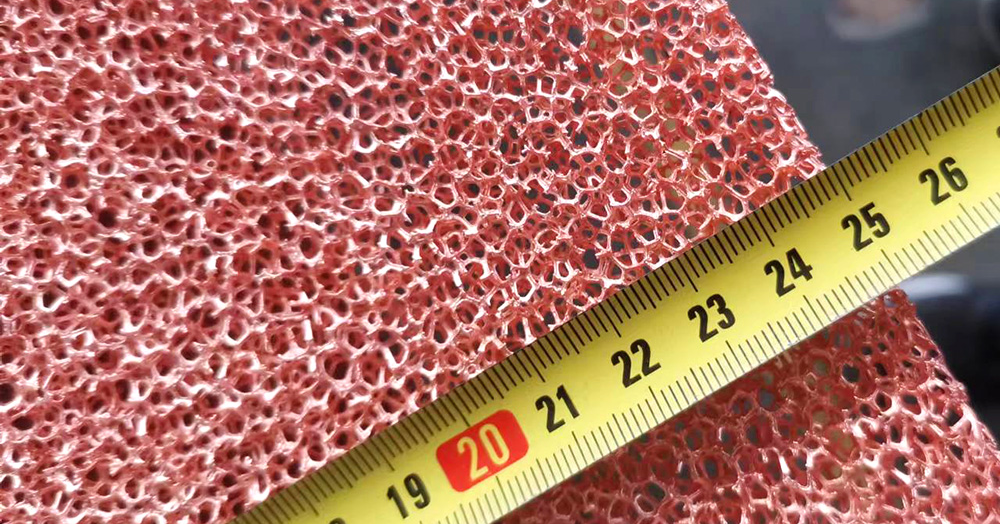

The structure of these two heat pipes has a huge negative impact on the thermal conductivity, so the foam metal material gives researchers a new possibility to solve the problem of thermal conductivity loss in the material structure. It is estimated that the use of foam metal materials to make heat pipes or other heat-dissipating components will greatly improve the thermal conductivity, and have greater compatibility with air-cooled and water-cooled systems.