On many occasions, airdrop supplies to specific locations. For example, when earthquake relief is needed, medical equipment, first aid, etc., need to be used for rescue at the disaster-stricken point. The land road where the traffic has been damaged or is quite congested, so airdrop is the best choice. In order to ensure that the equipment reaches the ground safely, emergencies occur in the packaging box to reduce the impact of the ground on the contents.

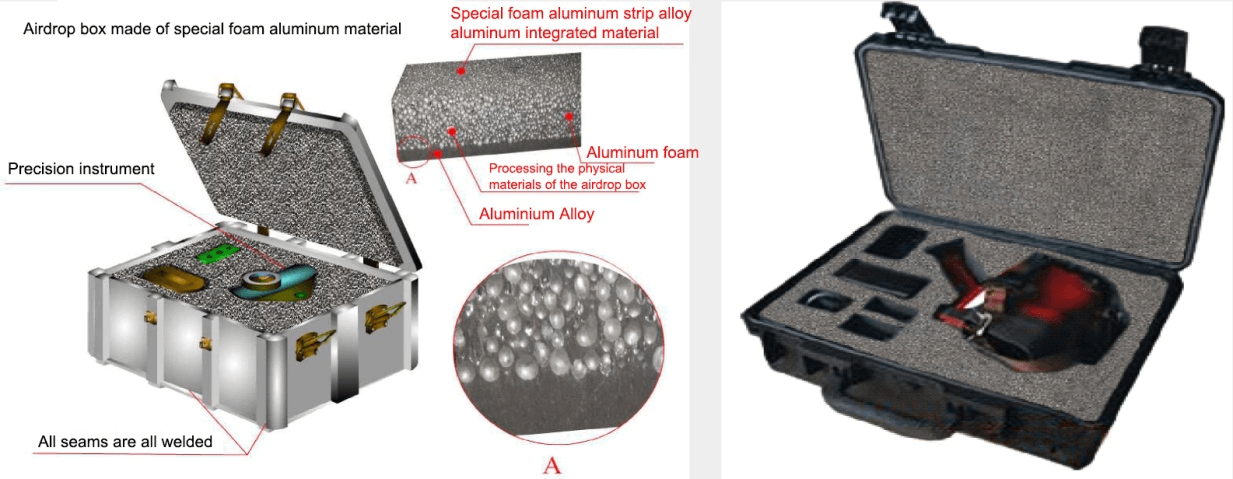

At present, the military standard airdrop packaging box is the Harding safety protective packaging box of the US military, which is made of high-density plastic foam. Many other airdrop boxes are dedicated boxes, that is, the buffer device is fixed in the box in advance. Even when the box is manufactured, the buffer device is installed at the same time and matches the geometric structure of the content, which is convenient for installing the content. It is a special box with higher cost and higher requirements on the geometric structure of the contents. As a result, many devices with the same functions but different geometric shapes could not complete the packing, which delayed the airdrop timing. The buffer module is generally located inside the box, which not only takes up the space of the box, but also reduces the loading capacity. Under the same loading capacity, the size and weight of the box are relatively large, which is not conducive to transportation.

Foamed aluminum is made by adding additives to pure aluminum or pure aluminum alloy through a foaming process. At the same time, it has the characteristics of metal and bubbles. It has low density, high impact absorption, high temperature resistance, strong fire resistance, and corrosion resistance. , Sound insulation and noise reduction, low thermal conductivity, high electromagnetic shielding, strong weather resistance, etc., have been widely used in aerospace ships, automobile collision avoidance, road sound insulation, building fire protection and other fields. It is feasible to use foamed aluminum materials in the production of airdrop boxes to make them have high shock absorption ability and to obtain durable airdrop boxes.

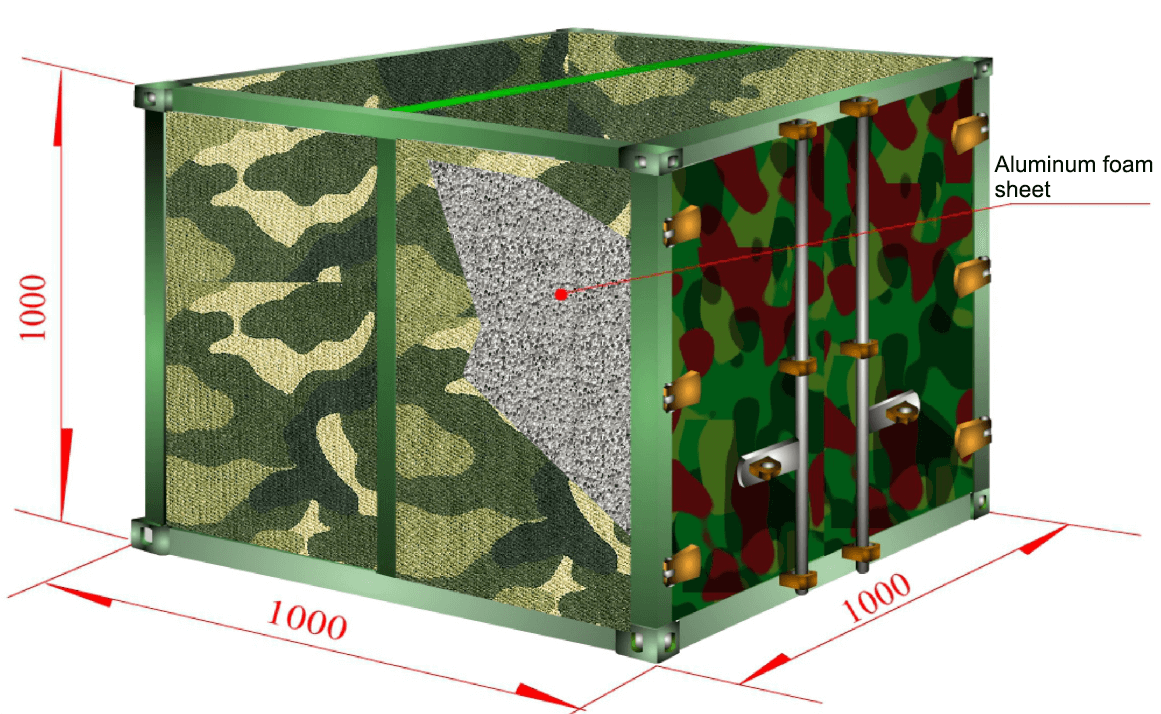

A foam aluminum air drop box buffer module, and a foam aluminum air drop box with the buffer module. The foam aluminum air drop box buffer module includes at least two laminated foam aluminum plates and compression springs arranged at intervals between adjacent foam aluminum plates. The compression spring is in a compressed state, the edge of the foam aluminum plate is provided with a clamping block for clamping and fixing the multi-layer foam aluminum plate, and the clamping block includes a first and a second clamping wall that abut on the outer foam aluminum plate surface , The first and second card walls are provided with connecting holes arranged at intervals, and the connecting holes are provided with screws and fastened to the board body of the foam aluminum plate; A compression spring is arranged between the foam aluminum plate and the foam aluminum plate has high impact absorption capacity, and the compression spring is used for buffering. This double impact absorption capacity prevents the foam aluminum airdrop box from damaging the contents when it hits the ground.