The heat dissipation of the vacuum vapor chamber is a relatively new heat dissipation method. The vacuum vapor chamber can be regarded as developed on the basis of the heat pipe. Although the heat pipe can help the heat to be exported faster, the heat pipe will inevitably lead to a relatively large radiator, which is not suitable for those occasions with stricter requirements. This has led to a heat dissipation method that is also fast in heat conduction, also uses a relatively large heat capacity, but has a relatively small volume.

This is the case with the vacuum soaking plate. Like the heat pipe, it uses a material that is liquid at room temperature but has a relatively low boiling point. It can absorb a lot of heat to conduct heat by relying on phase change. At the same time, the exterior adopts pure copper design with faster heat conduction speed. However, the vapor chamber is designed with a relatively large heating area, so that in the same time, the copper base absorbs more heat, the liquid inside the vapor chamber will be heated and vaporized more, and the heat conduction will be more efficient, which is also beyond the heat pipe. place. Combined with a large number of pure copper fins welded on the condensation end, and a powerful fan, the heat is completely exported into the air. Of course, the biggest advantage of the vapor chamber is that its plate-like shape is suitable for the heat dissipation of thinner electronic components such as graphics cards, CPUs, and high-power LED lights.

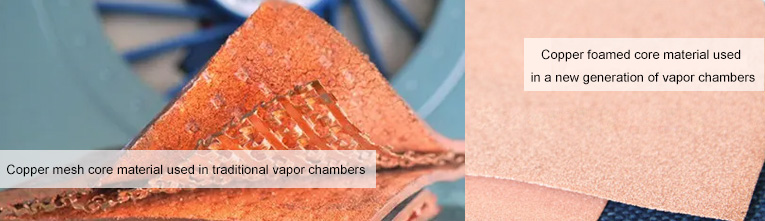

Obviously, the uniform pore structure of the foam metal has a larger thermal conductivity specific surface area, better capillary action for the copper mesh structure, and even saves the process of sintering copper powder on the inside of the substrate, and the use of low-cost manufacturing of smaller size and higher heat dissipation efficiency The vacuum vapor chamber becomes possible.