With the continuous improvement of the integration of computer accessories, the status of heat dissipation is becoming more and more important. A chip the size of a fingernail integrates as many as ten million transistors. The quality of heat dissipation will directly affect its working conditions. Therefore, the use of CPU and Graphics cards must use heat dissipation equipment, and the market capacity is huge. With the continuous updating of IT industry technology and the increasing degree of integration, heat dissipation has become a bottleneck for the development of many technologies.

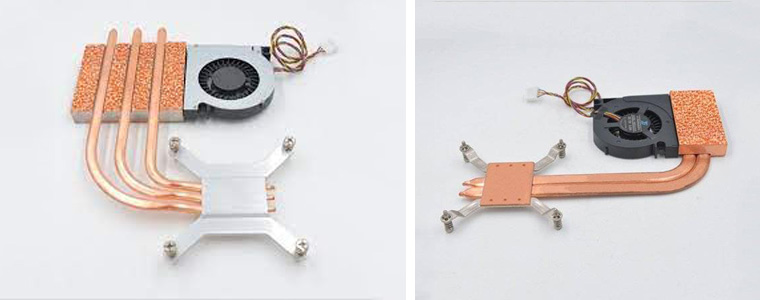

With the continuous development of foam metal materials, foam copper as a heat pipe and vacuum vapor chamber made of die cores increasingly reflect its superiority in CPU and graphics card heat dissipation, because of high porosity, the same heat dissipation efficiency, and foam Copper-made heat pipes and vapor chambers are much smaller than sintered cores and wire mesh cores. On high-power equipment, they have the characteristics of fast one-way heat dissipation and high stability.

More and more industry-leading manufacturers have entered the substantial production stage of foamed copper thermal components, which will bring a new revolution to the development of smaller, lighter and faster computer products.