Foamed aluminum is a kind of multicellular material, it is a kind of lightweight structural material. It has excellent performance and large deformability. It is a good energy absorbing material. It is widely used in automobiles, aviation, aerospace and other fields. It is especially suitable for various anti-collision buffer structures. Because it is usually used as an impact protection material, it is Dynamic shock compression performance has also received extensive attention. Usually foamed aluminum is designed as a sandwich panel structure, that is, a so-called “sandwich” structure composed of a metal panel and a foamed aluminum core. The aluminum material has its own characteristics and at the same time solves the problem of its low strength, which is a very promising structure.

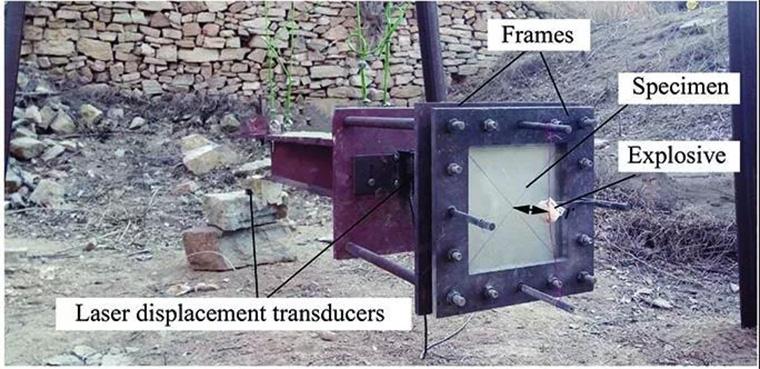

Aluminum foam material has the characteristics of damping and absorbing shock energy, but the strength of a single aluminum foam material is low. In order to reduce the damage of explosion impact load on the bottom column of the frame, a layer of aluminum foam material is added between the two layers of steel plate to form a multi-layer composite anti-explosion structure, so as to realize the functions of explosion protection and shock attenuation. When the explosion shock wave affects the composite structure, the aluminum foam produces plastic deformation and is compacted. Due to the low impedance of the aluminum foam shock wave, the strength of the stress wave can be greatly weakened. In this process, the energy of air shock wave is reduced, and the explosion-proof ability is improved compared with that of monolayer material.