Aluminum Foam Value in Industry

1. The mechanical properties of aluminum foam materials are mainly reflected in the energy consumed in the collapse process and the achieved absorption and buffering, which greatly expands the application range of aluminum foam materials.

2. Aluminum foam ingots: The slow-release casting foaming process has refreshed the largest aluminum foam products in the world today.

3. Aluminum foam composite board: single/double-sided material (aluminum plate, steel plate, etc.), non-metal (wood board, marble, fiberglass, fiber basalt, fiber aramid, carbon fiber, rubber, PE, etc.), foam is a base material , it can be single-layer and double-sided composite, and has the characteristics of light structure, high rigidity and good energy absorption.

Application: Widely used in indoor and outdoor decoration (decoration) materials, heat insulation and sound insulation walls and inter-node performance buildings, furniture, boxes, etc.; road sound barriers, ships, high-speed rail, train equipment, car structure, engine room sound insulation panels, etc.

4. Composite board (aluminum board/wood board/steel plate): aluminum foam is the middle sandwich layer, upper and lower layers (aluminum board/wood board/steel plate), hot-pressed bonding, it can meet the needs of the carriage by adjusting the material and size of crystalline aluminum foam and aluminum board Different performance requirements of crystalline materials for structures, floors, boxes, buildings, furniture, etc.

5. Composite board: It has the characteristics of light weight, high strength, high flatness, fire prevention, anti-corrosion, simple installation, time saving, material saving, low installation cost, etc. It is a new product selected for curtain wall materials at present, suitable for high-rise buildings, earthquake The exterior wall and interior decoration of strip buildings are favored by the decoration industry and customers due to the exquisite texture of natural marble. The composite of 3mm5mm marble and 10mm15mm aluminum foam plate can not only improve the performance characteristics of marble, but also reduce expensive The amount of marble used to reduce the cost of decoration.

6. Fiberglass (fiber basalt, aramid wire) composite board: the upper layer is sandwich material (fiber basalt, aramid wire), and the middle layer is fiberglass, which has excellent mechanical properties and low price.

7. Carbon fiber composite board: The middle is aluminum foam base, and the upper layer is carbon fiber composite sandwich material. This material has become a new dual-use military and civilian due to its light weight, high strength, large modulus, electrical conductivity, thermal conductivity, far-infrared radiation and many other excellent properties. It is widely used in aircraft, ships, trains and other casings.

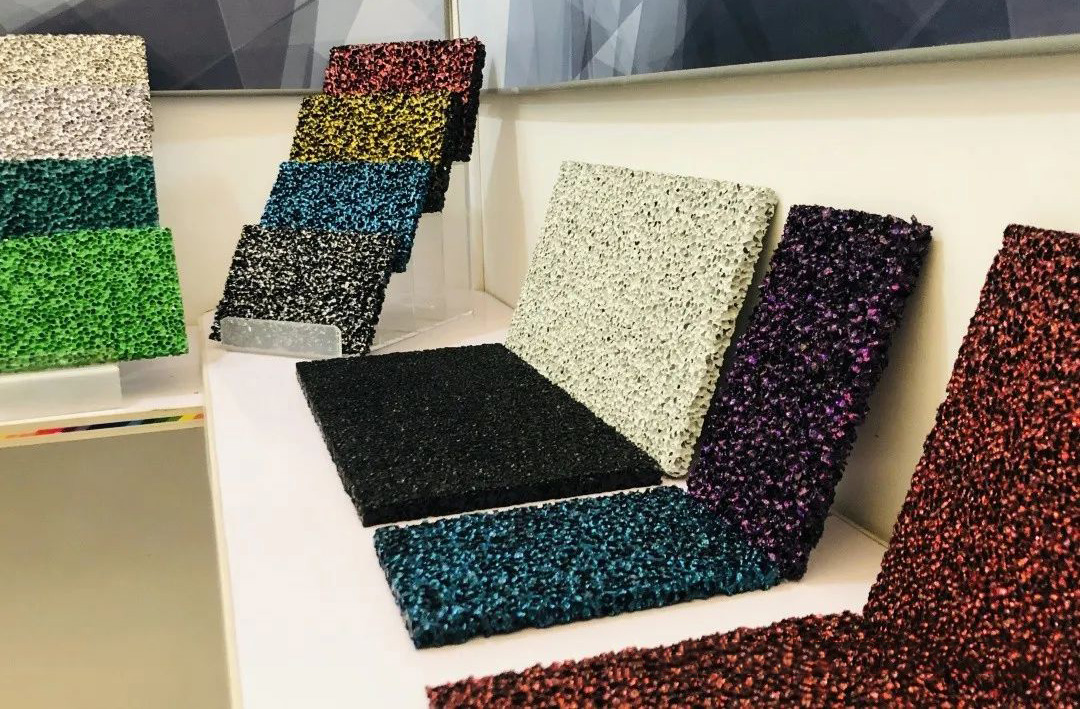

8. Foam color board: Foam can be made into various patterns, forming dry and strong adhesion on the surface of the foam, becoming a high-quality decorative product inside and outside the building.

Scope of application: Widely used in indoor and outdoor decoration materials, sound-absorbing panels, road sound barriers, energy-absorbing buffers, fire-proof and explosion-proof panels, etc.