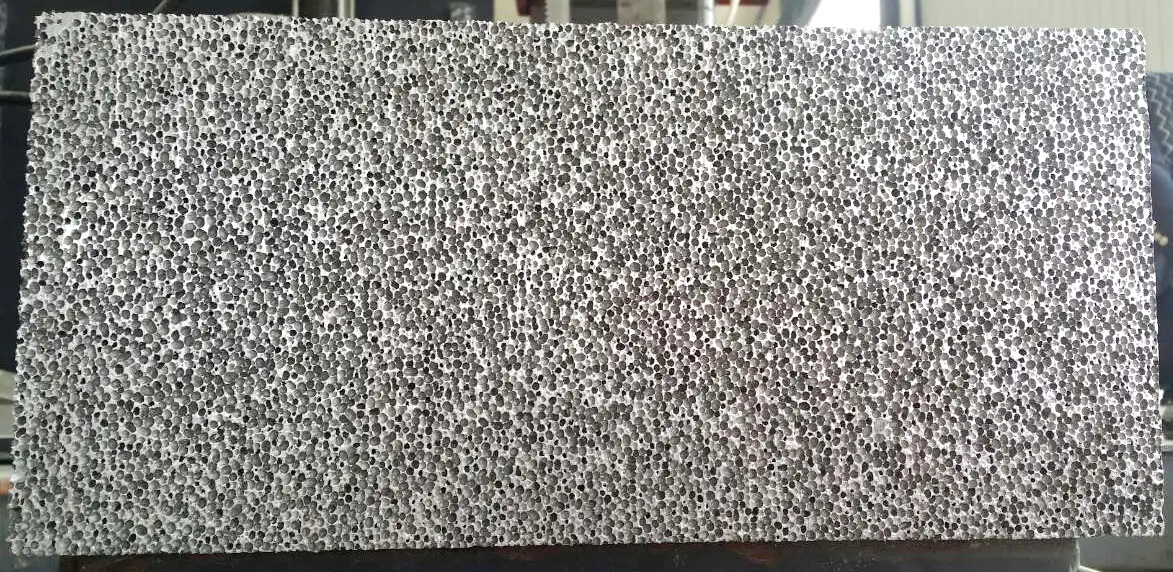

Aluminum foam is made by adding additives to pure aluminum or aluminum alloy, and it is made by foaming process, and it has the characteristics of metal and bubbles at the same time. It has low density, high impact absorption ability, high temperature resistance, strong fire resistance, corrosion resistance, sound insulation and noise reduction, low thermal conductivity, high electromagnetic shielding, strong weather resistance, filtering ability, easy processing, easy installation, and high forming accuracy. , Surface coating can be carried out.

Aluminum foam has excellent physical, chemical and mechanical properties and recyclability. These excellent properties of aluminum foam make it have broad application prospects in today’s material field, and it is a promising engineering material, especially in the transportation industry, aerospace industry and building structure industry.

Why is the development of aluminum foam so fast? It is because of the many advantages of foamed aluminum, such as the density is 0.1-0.4 times that of metal aluminum; its bending stiffness is 1.5 times that of steel; the damping performance is 5-10 times that of metal aluminum. When the porosity of 84% aluminum foam is 50% deformed, it can absorb more than 2.5MJ/m3 of energy.When the sound wave frequency is between 800-4000HZ, the sound insulation coefficient of closed-cell aluminum foam is above 0.9. When the electromagnetic wave frequency is between 2.6-18GHZ, the electromagnetic shielding capacity of foam aluminum can reach 60-90dB.

Structurally: the foamed aluminum is easy to cut, drill, and glue; it can be bent into a desired shape by molding; it can be surface-treated with organic or inorganic paint; it can be covered on both sides to form a large-sized lightweight, high-rigidity board. Aluminum foam material can be installed at high places without mechanical lifting equipment, such as: ceilings, walls and roofs, etc., can be mechanically or directly connected and fixed with screws, or can be glued to walls or ceilings with adhesives . Sheet metal – aluminum foam – The “sandwich” structure formed by sheet metal inherits the excellent properties of aluminum foam and has high flexural strength, which can be used as new building materials, high-rigidity structural parts of rolling stock, etc.