If a metal material is lightweight and can absorb energy, it will definitely attract the hot eyes of automobile manufacturers.

Spherical porous aluminum – also known as aluminum foam – is such a “treasure” in the eyes of automobile manufacturers. Former U.S. President Barack Obama’s car “Army One”, known for its bulletproof, riot-proof high security, using a large number of aluminum foam material.

This appearance like a sponge foam aluminum, just pure aluminum changed a shape, but its functionality is an explosive increase: lightweight, low density, heat resistance, impact resistance, permeability, sound absorption, insulation, electromagnetic shielding, resistance, corrosion resistance and so a bunch of advantages to come, which opens up a flawless imagination for its application.

1、The energy damage caused by the impact is absorbed by aluminum foam

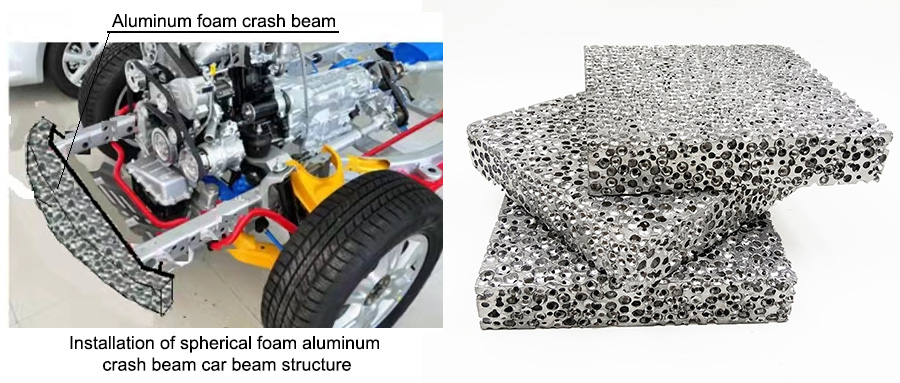

Ordinary car front longitudinal beam structure, steel crash beam lacks energy absorption capacity, and the low-speed energy-absorbing box it carries can only absorb little kinetic energy to cushion the low-speed impact; in order to cushion the high-speed impact, some low-intensity sections are set on the longitudinal beam, allowing the car engine to be partially deformed upon impact, which is actually a poor safety effect.

If the crash beam uses energy-absorbing spherical foam aluminum, safety can be effectively improved.

When an external impact or pressure acts on the aluminum foam, the energy is transferred to the microstructure of the aluminum foam, which is then dispersed and absorbed through these tiny channels and connections. In addition, because the material of aluminum foam is not recoil-elastic, the energy absorption effect is better.

After the impact, the foam aluminum crash beam of the car absorbs energy through deformation and releases the kinetic energy of the impact, which can make the body and car remain undeformed to achieve the effect of protecting the safety of personnel.

2、Reduce the weight of the car

For automobiles, especially new energy vehicles, the necessary path to energy saving and consumption reduction is to realize the light weight of the body.

The existence of a large number of small holes makes the density of aluminum foam lower, and light weight becomes another major characteristic, which can “carry” the “heavy responsibility” of car light weight while having safety.

3、To help the car noise reduction

If high safety, lightweight to meet the rigid needs of the car, then also can do the sound-absorbing effect of aluminum foam undoubtedly brings additional surprises for the car.

As the aluminum foam has a large number of small pores, when electromagnetic waves, sound waves and other energy through the aluminum foam, will be absorbed and dispersed by the electrons and ions in the pores. In this way, the effect of sound absorption is achieved.

In addition to the car silencer, the car floor, spacer, door sandwich panel and other car parts made of aluminum foam material can also achieve the effect of sound insulation and vibration isolation.

4、Respond to complex operating conditions

The surprise that aluminum foam brings to the car does not stop at the above-mentioned functions, because the operating conditions of the car are more complex and need to cope with the temperature, climate, long-term use and other conditions, aluminum foam can easily cope.

For the need to ensure driving comfort, reduce energy consumption and protect the equipment inside the car, the car needs to be insulated. Aluminum foam has certain pores and air layers that prevent the transfer of heat.

The car will also be exposed to different media and environments during the driving process, such as seawater, salt spray, acid rain, etc., which will have a corrosive effect on the metal parts of the car, affecting the stability of the body structure, shortening the service life and reducing the performance of the vehicle.

The aluminum foam is the effective response to these complex environments “tool”, aluminum foam products with good weather resistance, low moisture absorption, non-aging advantages. Its principle is that the surface is covered with a layer of alumina film, which can prevent aluminum from reacting with oxygen, moisture, acid and alkali substances in the external environment; the pore structure of aluminum foam can also play a buffering role to prevent corrosive media from directly contacting the material surface, thus achieving a protective effect.