Advantages of aluminum foam cushioning energy-absorbing material:

① lower yield strength, which can be deformed at a smaller compressive stress;

②With a wide compressive stress-strain curve. (ii) a wide stress plateau in the compressive stress-strain curve, which allows continuous energy absorption through deformation at almost constant stress;

③capable of achieving optimal energy absorption capacity by adjusting the relative density;

④ absorbing energy in the form of crushing, low rebound, less than 3% (the rebound rate of general polyurethane foam energy absorbing material is about 15%);

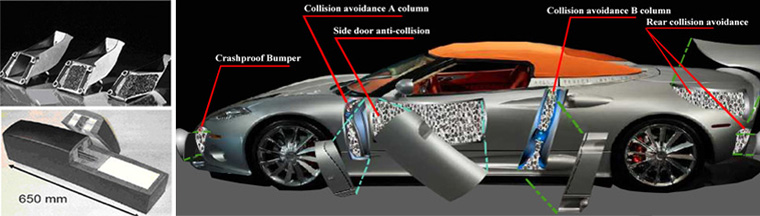

Compared with honeycomb structure, foam structure has more outstanding advantages, its cost is lower and its performance is better, aluminum foam structure has stronger resistance to buckling and fracture, more importantly, the mechanical properties of aluminum foam structure is isotropic, in addition, the aluminum foam structure is not easy to damage in a fire, in the processing and manufacturing can be made into curved or complex 3D shape, these are incomparable to honeycomb materials. Compared with other energy-absorbing materials such as polyurethane foam, aluminum foam structure has lower rebound rate, higher energy-absorbing platform stress, stronger energy absorption capacity, and also has the inherent properties of metal materials such as weldability, non-toxic, non-hazardous, green, and 100% recyclable. Considering the above properties of lightweight material aluminum foam, it is the preferred energy absorbing material and its application in the energy absorbing structure of the body should be improved.

Modern cars need to meet the energy saving, environmental protection, safety, comfort and other conditions, need a low density, non-combustible, high specific strength and can reduce the noise of multi-functional materials, but steel, aluminum, automotive composites, etc. can only meet one or two of the conditions, and often at the cost of reducing other performance. Aluminum foam is not only a lightweight material, but also has high specific stiffness and strength. If we talk about weight reduction function, sound absorption function or vibration reduction function alone, aluminum foam may not be the best choice, but if we consider that a structure needs to have the functions of light weight, energy absorption, sound absorption, heat insulation and vibration reduction at the same time, then the advantages of aluminum foam are more prominent. In Europe and the United States and other countries, people want to develop a “micro car”, but this can not reduce the size of the passenger compartment at the cost, so some people try to introduce a compact engine and reduce other structures, but this gives rise to new problems, such as the engine compartment smaller resulting in heat dissipation problems, energy-absorbing deformation interval smaller resulting in crash safety problems, etc. However, aluminum foam is a good medium to solve these problems. Aluminum foam is a multi-functional material with excellent mechanical, thermal and acoustic properties. Although the current cost is high due to the limitations of production technology, its outstanding advantages in the fields of energy saving, weight reduction, environmental protection and safety are sufficient to offset the high cost in the long run, thus making it possible to be used in large quantities in automobiles.