The noise in the cabin of a ship mainly comes from diesel engines. The noise in the cabin will not only interfere with and destroy the working performance of the ship’s own instruments and equipment, but also affect the use of telephones and telephony pipelines for communication, and if the crew is in a strong noisy working environment for a long time, pay attention And work ability will be reduced, affecting physical and mental health. For enclosed spaces, reverberation has a greater impact on noise, and sound absorption and noise reduction is an effective measure to effectively reduce cabin reverberation.

Traditional sound-absorbing materials mainly include: organic fiber materials (such as cotton fiber, wood fiberboard), inorganic fiber materials (such as glass wool, rock wool), and foamed polymer materials (polyurethane foam, polypropylene foam), but These materials are low in strength, brittle and easy to break, short service life, easy to deliquesce, easy to fly, and easy to form secondary pollution. Considering the special environment on the ship and the health requirements of personnel, light weight and sound absorption performance should be selected. Excellent, fire-resistant, flame-retardant, moisture-proof, dust-free, non-toxic, healthy and environmentally friendly materials. With the development of technology and manufacturing industry, a new type of porous sound-absorbing material has emerged, which is called foam metal material.

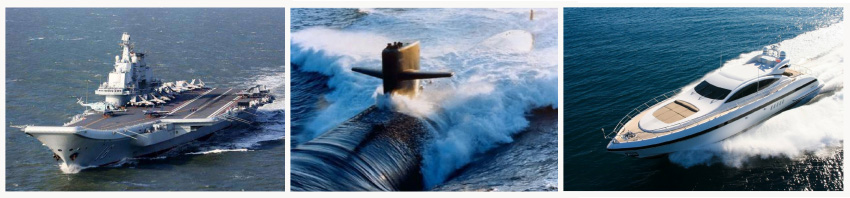

A sound-absorbing box composed of a foamed aluminum sound-absorbing board and a cavity behind it is installed in the submarine’s internal engine room, which can reduce noise by more than 20 decibels, which is conducive to the manufacture of silent submarines.

Other ships such as guided missile destroyers also need to use foam aluminum sound-absorbing panels to reduce noise in the engine room and make partition walls.

The composite structure of armor plates, foam aluminum plates, and steel plates for ship decks can increase the strength of the deck by more than 2 times, and the blast resistance and ballistic resistance can be increased by more than 2 times.

Foamed aluminum has low density, high strength, corrosion resistance, sound insulation, and non-combustibility. Used in aircraft carriers, ships, passenger ships, mixed ships, yachts, etc., foam aluminum can be used to make soundproof panels, indoor ceilings, flame-retardant floors, engine exhaust pipes, facility niches, etc.