Honeycomb Alumina Ceramic Foam Filter Casting With Porous

Honeycomb Alumina Ceramic Foam Filter Casting With Porous

Alumina Ceramic Foam Filter is a high temperature, corrosion-resistant filtration material made of alumina ceramic foam. It can withstand extreme temperatures in high-temperature environments and has excellent thermal stability and fire resistance. It can filter and separate liquids or gases at high temperatures and is suitable for a variety of high temperature processes and applications.

Production Description & Features

Alumina foam ceramic filter is applicable to the temperature of 1000C and is suitable for the filtration and purification of aluminum and alloy solutions. In order to meet the increasingly high quality requirements of aluminum castings, the use of alumina foam ceramic filter (plate) is increasingly important. In ordinary sand casting clean such as tide mold casting suitable and fixed mold casting suitable such as automotive aluminum parts casting also widely used filter.

Foam ceramic filter sheet advantages:

1. Purification of molten metal

2. Simplification of pouring system

3. Improve the metallurgical organization of castings

4. Reduce inclusions in castings

5. Casting qualification rate

6. Reduction of internal re-oxidation defects in castings

7. Reduction of surface defects after machining of castings

Classification of foam ceramics

Foam ceramics according to its material can be divided into silicon carbide foam ceramics, alumina foam ceramics, oxidation error foam ceramics, magnesium oxide foam ceramics and so on.

Alumina Foam Ceramic Filtration Process

The use of filtration process is mainly based on the following considerations, on the one hand, filtration makes the flow of aluminum liquid become orderly and relatively calm, and on the other hand, the solid slag in the metal liquid is effectively removed, the casting quality is rapidly improved.

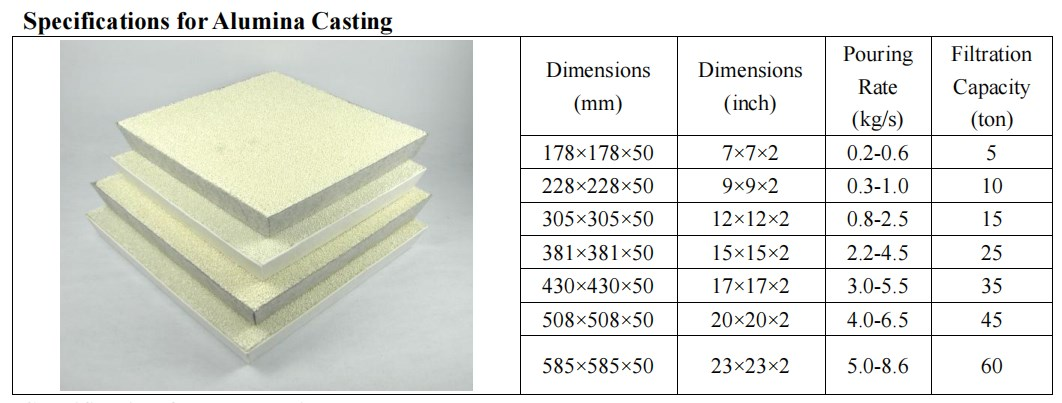

Alumina foam ceramic filtration products effectively remove solid inclusions in the molten metal, so aluminum alloy can be smoothly forged, aluminum foil manufacturing extrusion process, and other processes, to obtain the quality of the product. There is a choice of products from 10ppi coarse porosity to 40ppi very fine porosity, so there is always a product standard that suits your requirements. Ordinary sizes and special sizes required by customers can be met.

Physical and Chemical Properties

|

Material |

Alumina |

|

Color |

White |

| Pore Density |

8-60ppi |

|

Porosity |

80-90% |

|

Refractoriness |

≤1100℃ |

|

Bending Strength |

>0.6Mpa |

|

Compression Strength |

>0.8Mpa |

|

Volume-weight |

0.3-0.45g/cm³ |

|

Thermal shock resistance |

6times/1100℃ |

|

Application |

Aluminium, Aluminium alloys and other Non-ferrous alloys |

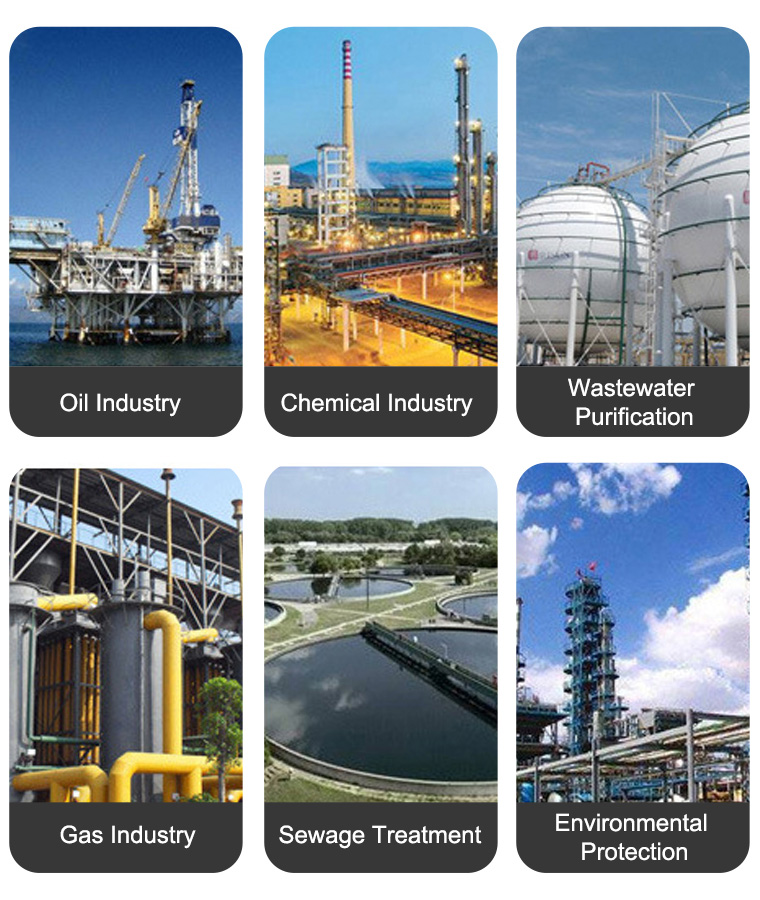

Product Application

Alumina ceramic foam filter is widely used in metallurgy, chemical industry, petroleum, electronics, environmental protection and other fields. It can be used to filter molten metals, high temperature gases, corrosive liquids and high viscosity liquids, etc. to realize effective separation and filtration.

Alumina ceramic foam filter is widely used for its high temperature resistance, corrosion resistance and fine filtration effect. It plays a key role in the industrial field for protecting equipment, improving product quality and realizing environmentally friendly production processes. Whether for metal melting, chemical processing or gas filtration, alumina ceramic foam filters provide reliable filtration solutions.

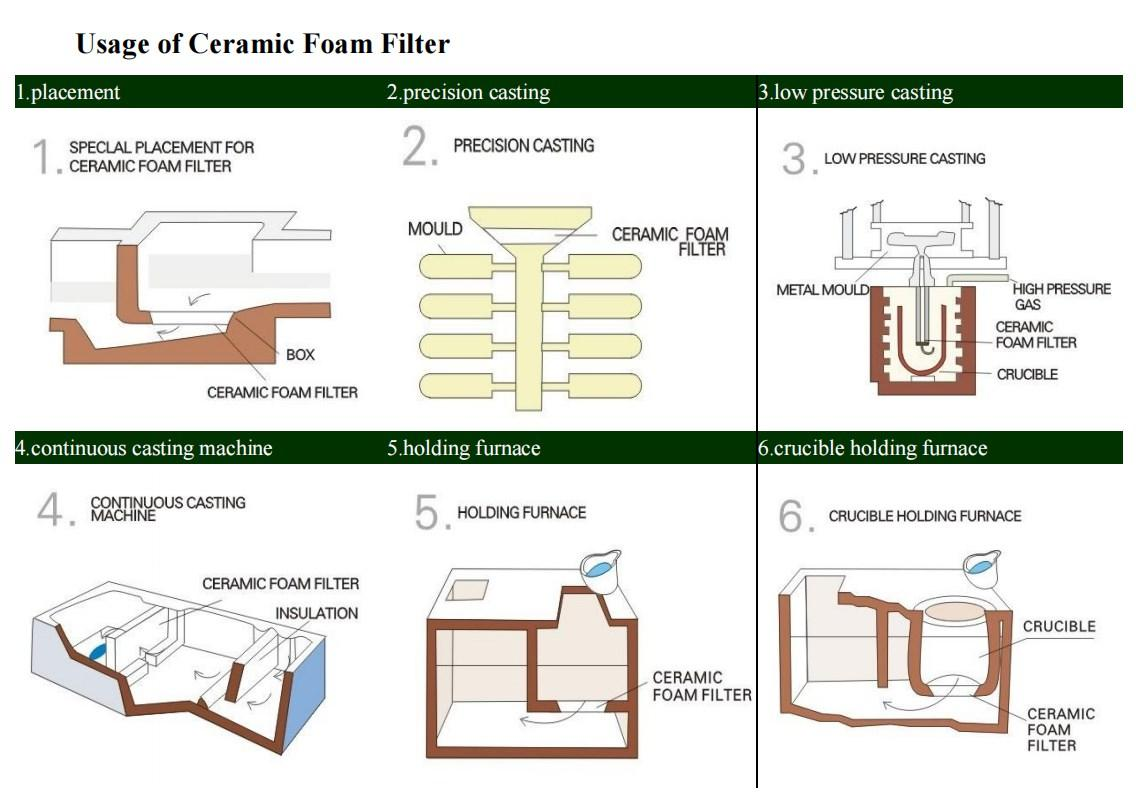

Instructions for use

Workshop

Packing Details

FAQ

1.MOQ: 100m²

2.Delivery time: around 20days after confirm order.

3.For LCL goods, the payment terms is 100% T/T payment in advance.

4.For full container, the payment terms is 50% deposit in advance, 50% balance before the shipment date.